TAKE NOTE (Insights and Emerging Technology)

The IRS wants to play “The Sims” at work. Well, it’s own version of the popular life-simulation video game, that is. According to a new request for information posted last April by the tax agency, it’s asking industry for its own, IRS mission-specific version of the game.

The IRS is looking for an “interactive prototype that simulates real-life events (similar to those that drive popular video games like ‘The Sims’) when its populated with statistical data about United States (US) household incomes and family sizes to create, track and generate output triggers for tax-related events,” the RFI read.

The tax agency is also requesting a report on artificial intelligence- and non-AI-based data modeling or prototyping tools for the government to simulate real-life events.

The project will allow the IRS to “generate, manage and control” synthetic tax data, or artificially generated data, to potentially be deployed at an enterprise level. The RFI is part of the Pilot IRS program, which looks to streamline the acquisition process for new technology solutions at the tax agency famous for using decades-old systems.

The synthetic data allows the IRS to test its systems, but it has trouble creating such data and keeping it current, the agency explained.

Interested in learning more about RPA? Download our FREE White Paper on “Embracing the Future of Work”

UNDER DEVELOPMENT (Insights for Developers)

Industry 4.0 – An Intelligent Introduction

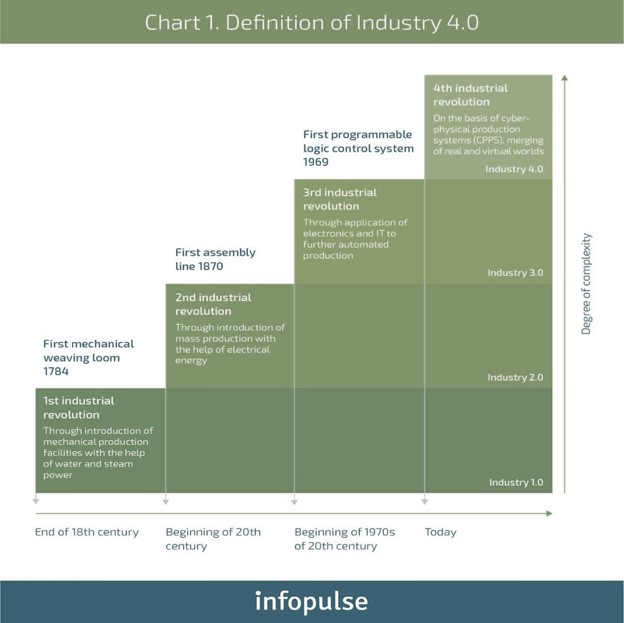

Industry 4.0 Definition

Everything nowadays is revolutionary to some extent. Irrespective of your feelings on “revolution”, all business sectors are in the midst of one. After all, almost everything in business is now changing to mirror the highest levels of customer experiences.

The 4th Industrial Revolution, sometimes called Industry 4.0, encompasses data automation and information exchange in different business areas. These include cognitive computing, the Internet of Things, cyber-physical systems, and cloud computing.

Understand The Principles of Industry 4.0

Like the other revolutions that have changed manufacturing and business sectors in the past, Industry 4.0 is hinged on four fundamental principles. These include:

- Interoperability: your organization’s sensors, devices, and departments should communicate with each other via the IoP{ Internet of People} or IoT (Internet of Things).

- Information transparency: the information systems used for businesses nowadays should be capable of creating virtual copies of your physical data using sensor data.

- Technical assistance: informational assistance is one of the categories of technical assistance. Here, systems are designed to support humans through the aggregation of information visualization comprehensibly. This enables people to make informed decisions. The other technical assistance category requires physical systems that will support people in performing tasks that are too exhausting, unpleasant, or unsafe for humans.

- Decentralized decisions: cyber systems and machines are autonomous. They can in Industry 4.0 make decisions, perform tasks, and assign jobs without human intervention.

Is SAP in on this REVOLUTION?

Yes!! SAP embraces Industry 4.0 holistically throughout a company to maximize the profit and avoid clashes between different departments. This means that a company can benefit from intelligent manufacturing in their factories with a seamlessly integrated supply chain execution.

The approach of SAP to Industry 4.0 combines three business concerns into one approach. These include:

- Focus on clients such that their needs form the basis of all your decisions.

- The reinvention of production through the use of intelligent processes and assets that will dynamically adapt to market changes and enable customization.

- Connection of your entire company and the coordination of logistics, services, and sales with your production process.

– Dig Deeper –

INDUSTRY 4.0

Q&A (Post your questions and get the answers you need)

Q. We are beginning to look at implementing S/4HANA. The terms Greenfield and Brownfield are being used to describe ways to go about moving from ECC 6.0 to S/4 HANA. Can you describe each way?

A. In the upcoming years, SAP customers have a big decision to make. SAP will stop supporting ECC 6, which means customers need to think about making the jump to SAP S/4HANA.

But that’s easier said than done. Migrating all your data and operations—from finance to supply chain to human resources—to a new version of the SAP platform is a complicated process.

It’s a move, however, every SAP customer is going to have to make. We’ll parse the differences between the approaches you have highlighted, and try to help you figure out which approach fits your needs best.

Greenfield Deployment of S/4HANA

Like wiping a slate clean, a greenfield approach is essentially a reset button. A transition using a greenfield approach is a complete re-engineering of a business’ SAP processes and workflows. Additionally, any customization done on SAP ECC 6 is completely wiped away during a greenfield implementation. This certainly has its pros and cons. For a legacy enterprise that has been using SAP for a long time and has accumulated a lot of complicated and heavily customized code, a greenfield approach might be the fresh start needed to overhaul its use of SAP and reduce complexities.

This is what the “back to standard” movement among SAP customers is all about. Greenfield is also perfect for companies new to SAP, if they are moving their data over from a non-SAP system.

It’s worth noting that a greenfield implementation is what SAP recommends when making the jump to SAP S/4HANA. It can be done either on-premise or in the cloud, and allows users to predefine migration objects. From a cost standpoint, greenfield implementations result in lower total-cost-of-ownership (TCO) and time-to-value according to SAP.

Brownfield Deployment of S/4HANA

If greenfield is a complete overhaul, then a brownfield approach is more like an upgrade of your SAP ERP. You can get SAP S/4HANA up and running, and also keep your tried-and-true business processes, along with the customization’s you’ve been using.

That said, you don’t have to bring everything over. Brownfield lets users reevaluate and edit their existing processes, and port over the ones that are working. On paper, a brownfield approach is both the cheapest and fastest implementation strategy. It’s also a lot less risky than greenfield. But SAP sees brownfield as an innovation block. The success of the implementation lives and dies by how well your current workflows and systems are replicated. This doesn’t any business process re-engineering to cut through the complexities and poor design and custom code of your current process.

SAP recommends that because of all the complexities that come with porting over the customization’s and workflows, a brownfield implementation is best done on-premise.

Brownfield is best for customers who are looking to continue using their current solutions and rapidly convert from SAP ECC 6 to SAP S/4HANA.

I would recommend you look into a 3rd way namely “Hybrid”.

Cheers!