TAKE NOTE (Insights and Emerging Technology)

A whole new category of protests could open up for situations where prime contractors decide to custom-build their solutions. A federal court has ruled that a commercial company can protest if its product is not part of a solution that a prime contractor proposes for a customer.

If the decision holds, it could send shockwaves through the contracting community because it would create a brand new category of protests when prime contractors decide to custom-build the solution instead of using a commercial product.

For the case at hand, the National Geospatial-Intelligence Agency awarded a $376.4 million contract called SAFFIRE in 2021 to CACI International for an intelligence analysis tool.

Percipient.ai filed a protest in January 2023 at the U.S. Court of Federal Claims, arguing that its commercial product should be part of CACI’s solution.

NGA underutilized the demos that Percipient offered, Percipient claims in its protest. CACI also evaluated Percipient’s Mirage product, which is used to analyze unstructured data.

Percipient claims that because its product is commercial, federal procurement laws require government agencies to use that offering instead of building something new from scratch.

It is a similar argument that Palantir used to fight its way onto the Army Distributed Common Ground Systems-A program for battlefield intelligence technology. But in that situation, Palantir wanted to pursue the opportunity as a prime and compete against Raytheon.

NGA argued that Percipient didn’t have standing to protest because it couldn’t be the prime contractor. Percipient also missed the window for protesting the terms of the solicitation, NGA claimed.

In May 2023, the U.S. Court of Federal Claims denied Percipient’s protest because the procurement in question was a task order and only the Government Accountability Office has authority over those.

The Court of Federal Claims did not rule on the validity of Percipient’s commercial product argument and told the company it should go to GAO. But by that point, it was too late for Percipient to go GAO.

Percipient instead took its argument up to the U.S. Court of Appeals for the Federal Circuit, where two of the judges hearing the appeal reversed the lower court’s ruling in a decision handed down.

Both government agencies and prime contractors are required to conduct market research to determine if commercial products are available, according to the majority opinion.

Percipient claims that CACI did not engage in adequate market research by evaluating the commercial product after NGA awarded the SAFFIRE task order.

The majority of the appeals court judges agreed, writing that the solicitation had market requirements for commercial products that NGA and CACI did not fulfill.

Now the case goes back to the U.S. Court of Federal Claims.

Interested in learning more about RPA? Download our FREE White Paper on “Embracing the Future of Work”

UNDER DEVELOPMENT (Insights for Developers)

MES Driven Consumption with EWM and Digital Manufacturing

Intro

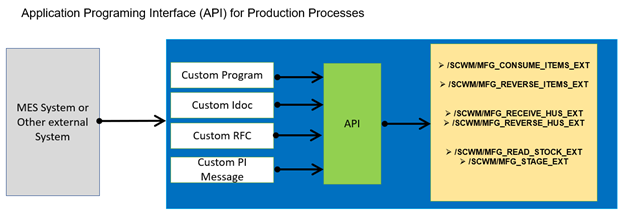

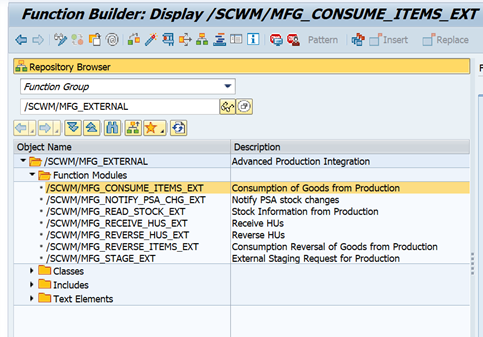

Back this month is our resident EWM expert Shailesh to explain how the usage of EWM MES Function Modules, especially, Consumption from Production FM /SCWM/MFG_CONSUME_ITEMS_EXT can be leveraged for Automation of Consumption for Single, Cross Order Items, Crate Parts & Manually staged Items(Adhoc Transfers). These FMs are building blocks of MES EWM integration and are highly used in Digital Manufacturing system.

All the EWM MES FM starting from /SCWM/MFG_* are primarily used in Staging, consumption & Reversal, GR & GR reversal and are building blocks for Digital manufacturing

For automation of the consumption process, or the staging, the external Function modules can be called. All *MFG*EXT function module can be called from own custom program like from PPF, or from Idoc. Not necessary to have MES system for using these FMS, even with simple S/4 HANA, embedded EWM or Decentralized EWM, these /SCWM/MGF_* FMs can be seamlessly used for Automation like Auto GI during receiving. These FMs are provides seamless integration for Digital Manufacturing Integration using Advanced Production Integration APIs.

With EWM 9.2, an internal API was introduced for an easy integration of the EWM production processes with Manufacturing Execution Systems (MES)

- Provide an easy-to-use programming interface for receipt (and reversal) of handling units.

- Provide an easy-to-use programming interface for Consumption (and reversal) of handling units

- Provide an easy-to-use programming interface for reading the HUs stocks, the probable HUs to be consumed in a Manufacturing Order.

How to Use /SCWM/MFG_CONSUME_ITEMS_EXT

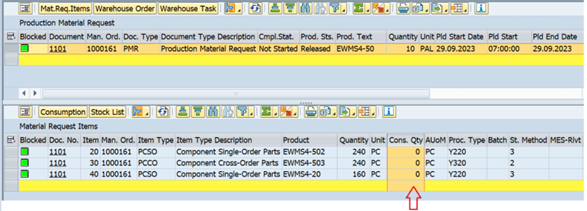

Function Module /SCWM/MFG_CONSUME_ITEMS_EXT can be widely used to consume Production material requests (PMRs) with Single, Cross, Crate Part as well manually staged Item. Lets take a look at the scenario below.

A PMR is created with Single and Cross items have been created with creation of Manufacturing Order in S4 system.

Since, no consumption has been carried, hence consumption quantity is marked as zero in PMR document. Once staging is performed, stocks are moved to Production Supply Area (PSA). The components are packed in handling units and labeled and moved to PSA.

– Dig Deeper –

What is MES?

Q&A (Post your questions and get the answers you need)

Q. What is SAP MII?

A. SAP MII (SAP Manufacturing Integration and Intelligence) is an SAP application for synchronizing manufacturing operations with both back-office business processes and standardized data. It functions as a data hub between SAP ERP and operational applications. It also provides analytics and workflow tools for identifying problems in the production process and improving its performance.

How does SAP MII work?

As its name implies, SAP MII consists of two main components. The integration component uses web standards to link SAP ERP and related business applications with plant floor applications. So, for example, Extensible Markup Language (XML) could be used with the Java programming language to include customer relationship management (CRM) with plant floor applications in a consistent user interface (UI). It employs web server technology to extract and aggregate data from multiple sources. It can also be made accessible from a variety of devices. When paired with SAP Plant Connectivity software and run on the Hana in-memory database, SAP MII can help to enable global visibility into manufacturing operations.

The intelligence side is intended to provide real-time analytics of manufacturing operations, using visualization tools and dashboards to show key performance indicators (KPIs) and alerts. Operations managers, business executives, plant employees and suppliers can use these features to make short-term production decisions. SAP MII can also help manage continuous improvement programs, such as Lean Six Sigma.

SAP MII works within a single plant or across multiple plants, connecting manufacturing for optimal supply chain management, as part of the industrial internet of things (IIoT) ecosystem.

Cheers!