TAKE NOTE (Insights and Emerging Technology)

Chatbots can now invent new recipes (with mixed success), plan vacations, or write a budget-conscious grocery list. So what’s stopping them from summarizing secret intelligence or drafting detailed military operations orders?

Nothing, in theory, said AI experts from the independent Special Competitive Studies Project. The Defense Department should definitely explore those possibilities, SCSP argues, lest China or some other unscrupulous competitor get there first. In practice, however, the project’s analysts emphasized in interviews with Breaking Defense, it’ll take a lot of careful prep work, as laid out in a recently released SCSP study.

And, they warned, you’ll always want at least one well-trained human checking the AI’s plan before you act on it, let alone wire the AI directly to a swarm of lethal drones.

“Right now you can go on ChaGPT and say, you know, ‘Build for me a schedule for my kids’ lunch boxes for like the next five days,’” said Ylber Bajraktari, a veteran Defense Department staffer now serving as a senior advisor to SCSP. With a little more programming, he added, “it could connect to Instacart or whatever [and] can order all of those instantaneously, and that will get shipped to you.”

“The technology is there,” Bajraktari said. “The question is plugging those in.”

Plugging in intelligence databases and military command systems, of course, will take a higher standard of engineering than automating menus.

Interested in learning more about RPA? Download our FREE White Paper on “Embracing the Future of Work”

UNDER DEVELOPMENT (Insights for Developers)

EWM Understanding Inbound Delivery Status Updates

Intro

Back this month is our resident EWM expert Shailesh to help us understand how EWM updates different statuses of Inbound delivery in GR process, and how Unloading, Planned Putaway and Putaway status of EWM Inbound deliveries are updated with and without Storage process.

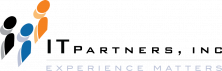

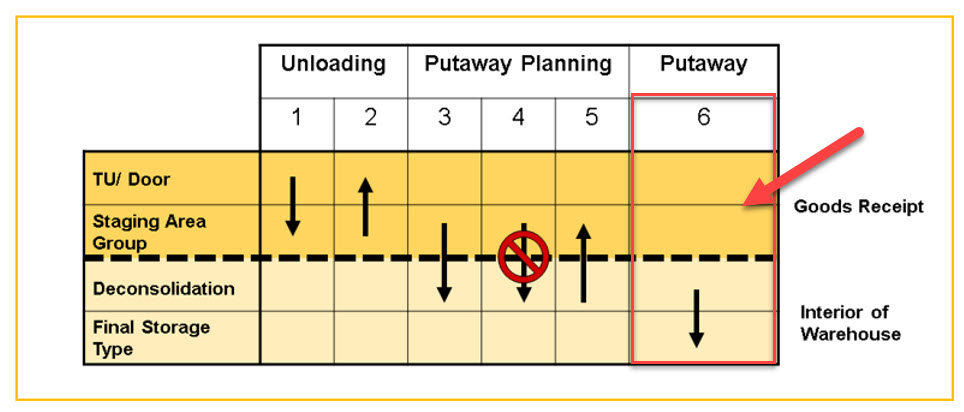

Extended Warehouse Management (EWM) updates the inbound delivery corresponding to the goods receipt activities. For the goods receipt process (GR process), EWM maps the warehouse with the goods receipt and interior of the warehouse areas. This allows EWM to determine the point in time from when a putaway is planned, that is, from when a warehouse activity exceeds the limit for the interior of the warehouse. The following information belongs to the goods receipt area:

- Transportation units (TUs)

- Storage bins at warehouse doors

- Staging area groups

Unloading Status (Door Bin to Staging Area)

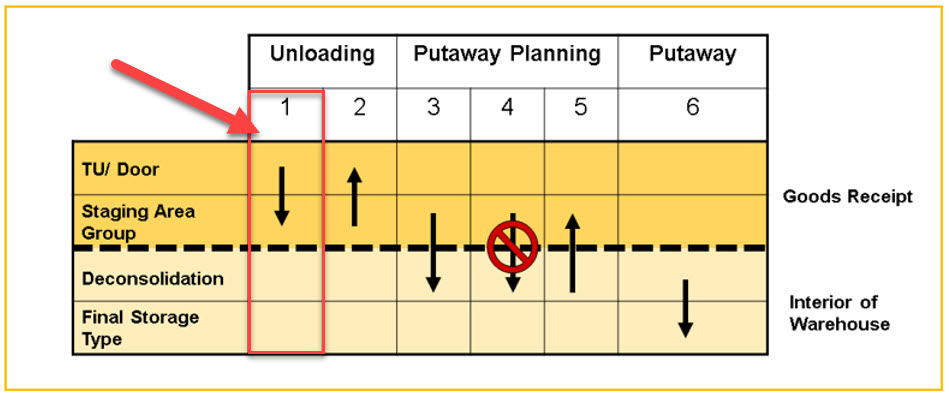

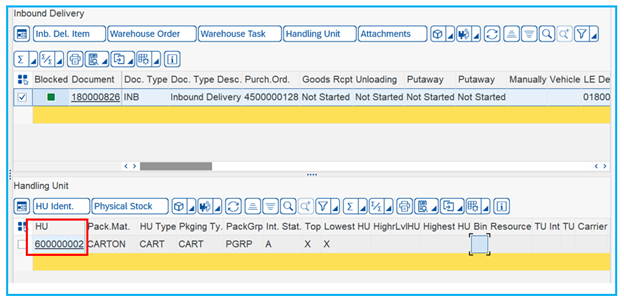

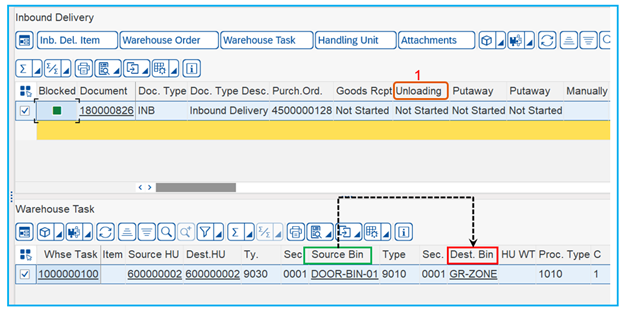

Graphic #1: An Inbound delivery has been created with respect to vendor PO, system is configured in such a way that Goods movement Bin is Door Bin with Unloading, Planned Putaway and Putaway status as not Started. In this example, lets move the HU from Door Bin (Goods Movement Bin) to Staging Area as highlighted below:

The Inbound delivery is packed into below HU as Highlighted.

The following rules apply for the status Unloading:

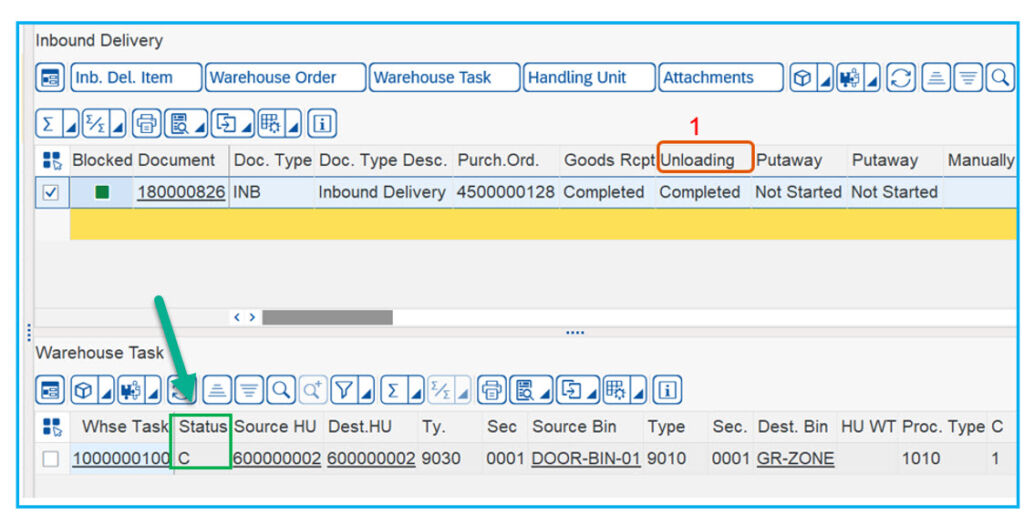

If an HU WT or a product WT with source HU is confirmed that is moving from a door to a staging area group, EWM sets the status Unloading in the inbound delivery (see number 1 in the graphic).

Before WT confirmation: Unloading Not started

After WT Confirmation: Unloading Status is completed

– Dig Deeper –

TT1z3Nk69OY

Q&A (Post your questions and get the answers you need)

Q. What is the difference between SAP MES and MII?

A. MES stands for Manufacturing Execution System, while MII stands for Manufacturing Integration and Intelligence.

MES is a software system that helps manage and monitor production processes on the shop floor. It typically provides functions such as production scheduling, material tracking, quality management, and performance analysis. MES is designed to optimize the production process and improve efficiency.

MII, on the other hand, is a software system that focuses on collecting and analyzing data from various sources across the enterprise. It provides a way to integrate data from different manufacturing systems and other sources, such as ERP systems, to create a unified view of production operations. MII is designed to provide real-time visibility into the performance of the manufacturing process and to facilitate data-driven decision-making.

The main difference between MES and MII is that MES is focused on managing the production process itself, while MII is focused on collecting and analyzing data to provide insights into that process.

MES is typically used by plant managers and operations personnel, while MII is used by analysts and other business users who need to understand the performance of the manufacturing operation as a whole.

We will be writing blogs on MES & MII soon, so stay tuned.

Cheers!