TAKE NOTE (Insights and Emerging Technology)

The General Services Administration has restarted the process for its Polaris government-wide IT solutions contract vehicle and reopened the portal for submitting proposals.

In a pair of SAM.gov notices Thursday, GSA said it also has given bidders a new submission deadline of Aug. 10 after a pause over nearly three months to re-evaluate the procurement. Companies and teams previously had until June 30 to get their proposals in.

Polaris has one track for contractors designated as general small business and a second for woman-owned SBs.

The most-debated aspect of Polaris’ solicitation, and subject of a prior protests, appears to have some changes in light of the GAO challenge and industry-wide worries.

For mentor-protege joint ventures, the protege or offering JV must include at least one primary relevant experience project or emerging technology relevant experience project in the proposal. No more than three examples can come from the mentor.

Prior language in the request for proposals had no requirement for a small business involved in either a general joint venture or mentor-protege JV to detail any relevant experience or past performance.

One might notice no reference to a ceiling figure in this article. That is because GSA removed the ceiling requirement via a class deviation to the Federal Acquisition Regulations back in March.

Interested in learning more about RPA? Download our FREE White Paper on “Embracing the Future of Work”

UNDER DEVELOPMENT (Insights for Developers)

The Top Three Enhancements in EWM Implementations

Intro

Back this month is Shailesh Mishra with another great Extended Warehouse Management (EWM) blog on the three inevitable enhancements in EWM SAP implementations.

The 3 most used enhancements in EWM implementation projects.

In most of complex EWM SAP implementations, the business requirement cannot be fully mapped with SAP standard solutions, and hence it becomes inevitable to use SAP EWM Badis to hook customer specific enhancements and put the own code to meet the business requirements. This blog is written on my personal experience with 5 EWM SAP implementations, where in every project, it becomes viable to use these enhancements to alter EWM SAP standard behavior and enhance to cater customer needs

SAP has provided tons of enhancements options in EWM SAP to enhance user-defined fields or to hook customer specific enhancements for a required EWM SAP business process, however, this blog is written to explain, the 3 most used enhancements in EWM SAP implementation projects.

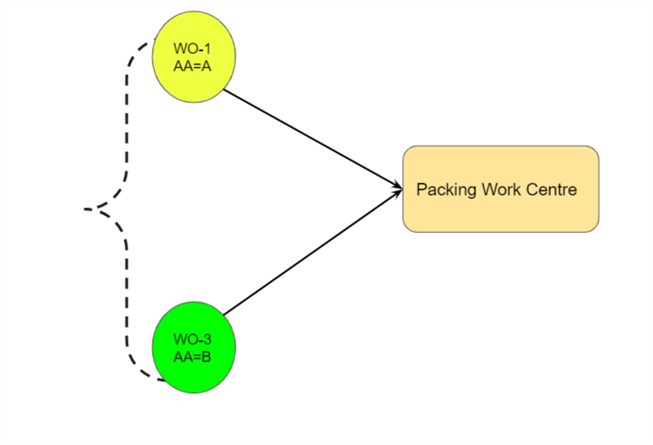

Consolidation of Warehouse Orders

Requirement for this Enhancement:

If one warehouse order is started earlier than its planned latest starting date and time, then related warehouse order should also start earlier so that in example all items that are needed to be packed together into a shipping Handling Unit (HU) arrive approximately at the same time at the packing work center. Therefore the packing step can start and also finish earlier than planned.

Example: warehouse order A is started in activity area “bulk”. Automatically the second warehouse order B (same delivery) is raised in priority for activity area “rack” so that both warehouse orders have a better chance to arrive simultaneously at the packing work center.

Solution:

A BAdI example implementation /SCWM/EI_CORE_POST_CONS_WHO for BAdI definition /SCWM/EX_CORE_CO_POST in enhancement spot /SCWM/ES_CORE_CO is delivered by SAP. The BAdI example implementation implements following logic:

”EWM SAP Warehouse orders for one delivery are consolidated by latest starting date and time. If one warehouse order is started earlier than planned the latest starting date and time of the other warehouse orders related to the delivery get updated.”

- The system checks the planned completion time of the EWM warehouse order that started earlier. Upon confirmation of its first warehouse task the planned completion time of the warehouse order is re-calculated based on its planned duration. The completion time serves as reference completion time and the planned duration as reference duration for related warehouse orders.

- The latest starting date and time of related warehouse orders is calculated based on the reference completion time minus the planned duration of the warehouse order.

- If the resulting latest starting time is in the future it gets rounded according to the configuration setting for resource management. If it is in the past the latest starting time is set to the current time.

The next enhancement is …

– Dig Deeper –

SAP WM vs. SAP EWM What’s the Difference?

Q&A (Post your questions and get the answers you need)

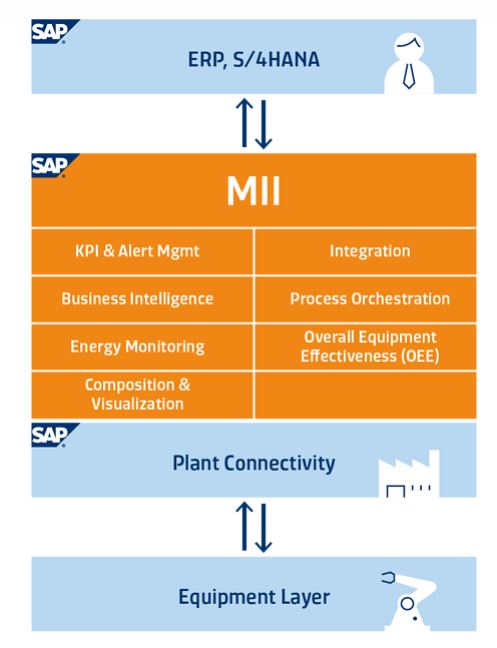

Q. What is SAP MII, MES?

A. SAP Manufacturing Integration and Intelligence (SAP MII) is a comprehensive platform for Manufacturing Execution (MES) and integration solutions. SAP MII allows for real-time production monitoring and provides extensive data analysis tools.

Using SAP MII, data can be integrated and combined with data from other business systems. This integration provides deep insights into the measures from SAP ERP down to the shop floor, and across shop floor operations and applications. These insights aid in decision making regarding equipment usage and shifting production priorities and also ensures necessary actions can be executed automatically or manually.

SAP MII solutions become the central component and orchestra tor for data-driven, evidence-based decision making. MII extracts and processes data from all critical business systems and displays integrated data to key stakeholders and decision makers. For instance, SAP MII can be used to view, collect, measure, and compare the performance of plants and assets with different automation system infrastructures.

To enable more valuable information, SAP Plant Connectivity (SAP PCo) can be used to connect shop floor equipment for the purposes of data collection and evaluation.

Have you looked into the SAP Digital Manufacturing Cloud (DMC)? The DMC enables the orchestration, execution and monitoring of production processes in hybrid system environments.

DMC is a complete MES solution, with direct integration with Shop Floor,

Could DMC replace MII as the new Manufacturing Execution System (MES)?

What do yo think?

Cheers!