Shailesh Mishra is a SAP EWM Senior Consultant. Shailesh has deep Expertise in implementing and offering SAP EWM best practices solution and EWM deployment options on S/4 Hana embedded versions and decentral versions supporting various business verticals like Pharma, Food industry and Manufacturing. Cross module knowledge of SAP ERP logistics like SAP MM, SD and Production Planning. Strong technical knowledge of SAP ABAP. You can reach him at [email protected].

Shailesh Mishra is a SAP EWM Senior Consultant. Shailesh has deep Expertise in implementing and offering SAP EWM best practices solution and EWM deployment options on S/4 Hana embedded versions and decentral versions supporting various business verticals like Pharma, Food industry and Manufacturing. Cross module knowledge of SAP ERP logistics like SAP MM, SD and Production Planning. Strong technical knowledge of SAP ABAP. You can reach him at [email protected].

Back this month is our resident EWM expert Shailesh to help us understand how EWM updates different statuses of Inbound delivery in GR process, and how Unloading, Planned Putaway and Putaway status of EWM Inbound deliveries are updated with and without Storage process.

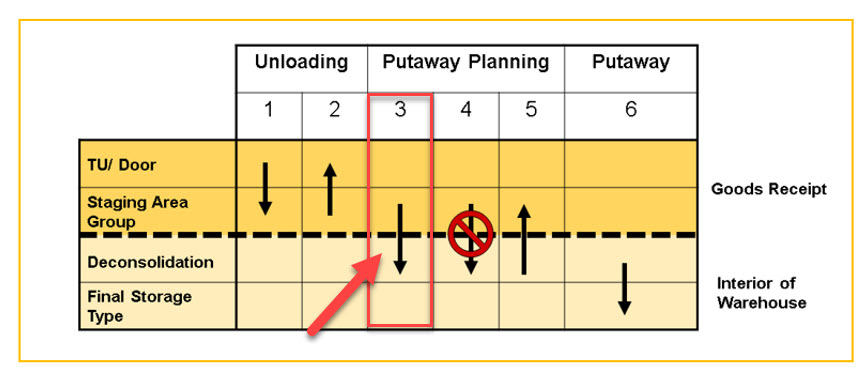

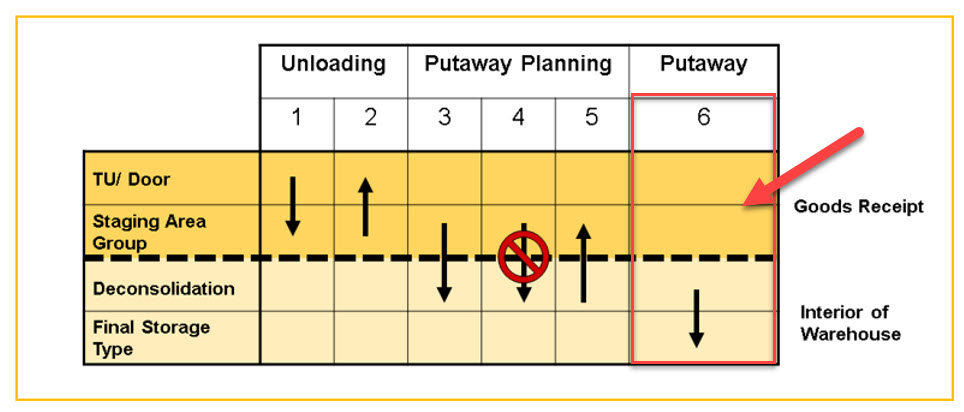

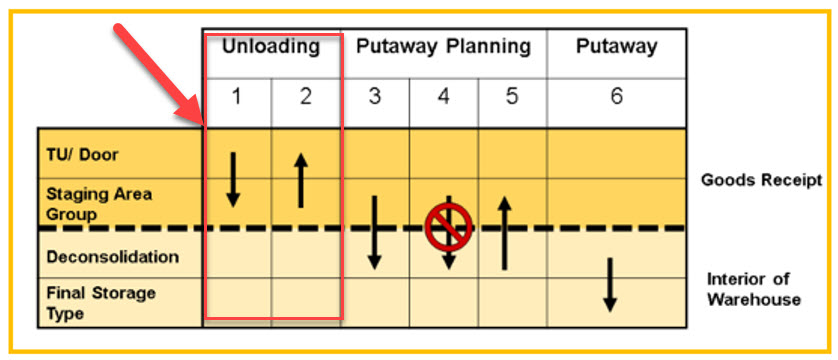

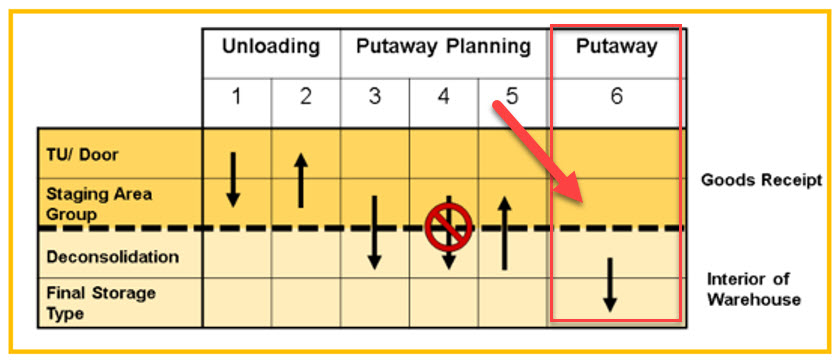

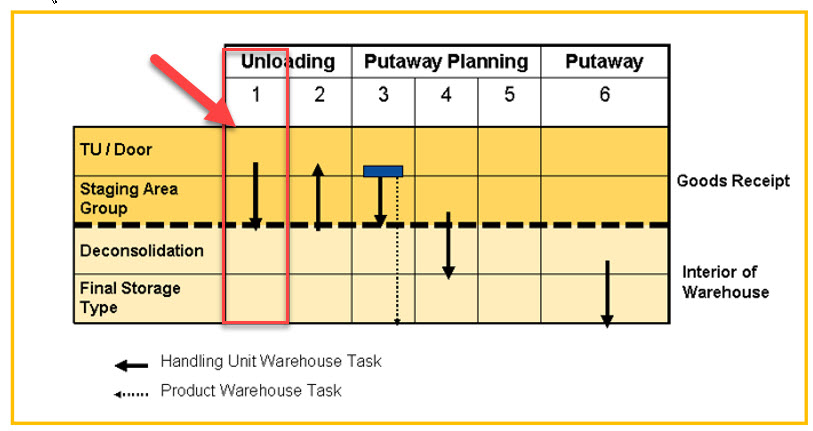

Extended Warehouse Management (EWM) updates the inbound delivery corresponding to the goods receipt activities. For the goods receipt process (GR process), EWM maps the warehouse with the goods receipt and interior of the warehouse areas. This allows EWM to determine the point in time from when a putaway is planned, that is, from when a warehouse activity exceeds the limit for the interior of the warehouse. The following information belongs to the goods receipt area:

- Transportation units (TUs)

- Storage bins at warehouse doors

- Staging area groups

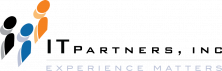

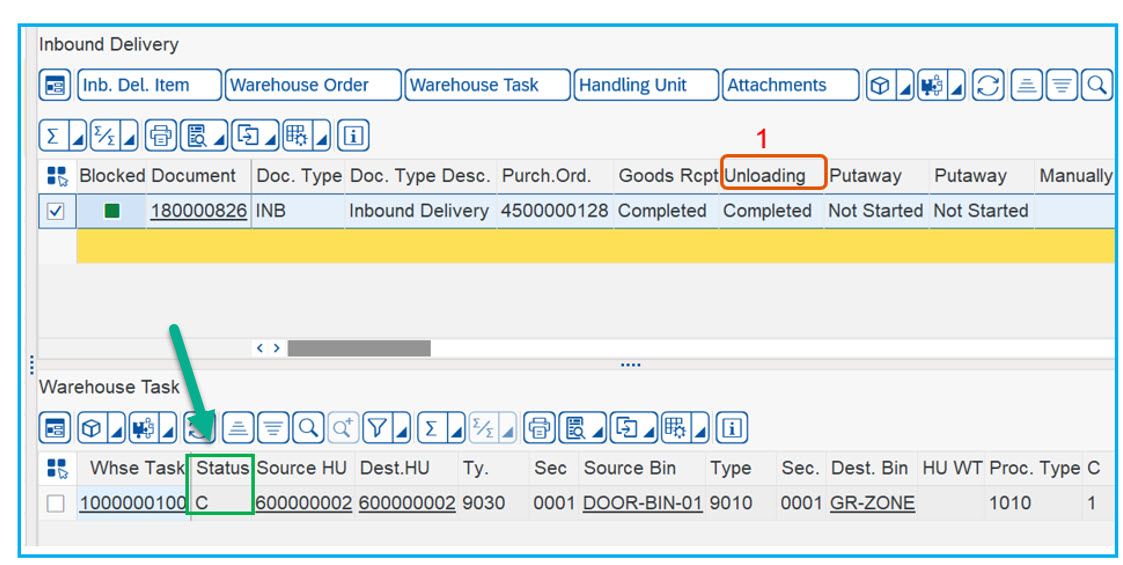

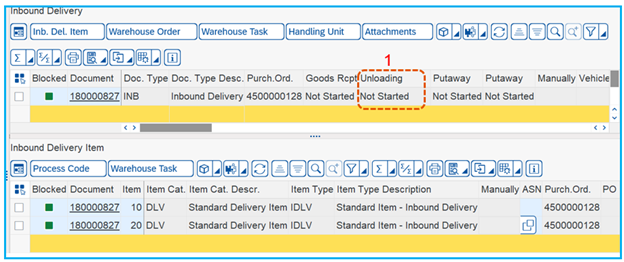

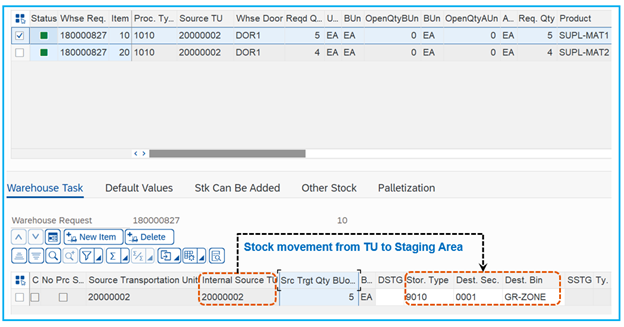

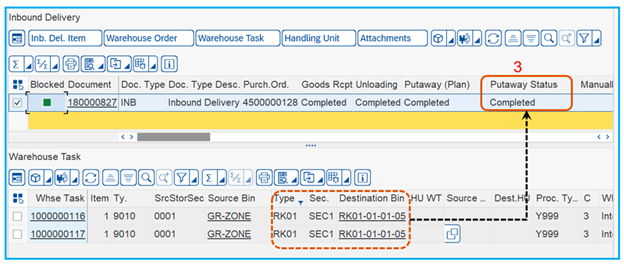

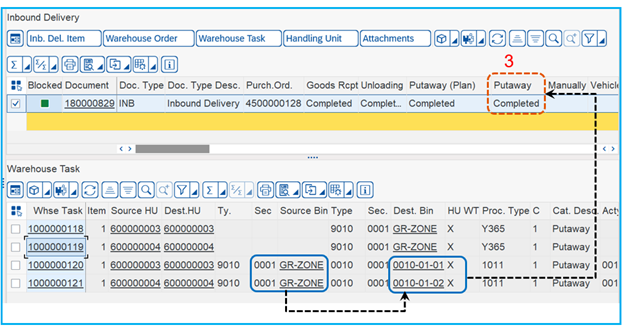

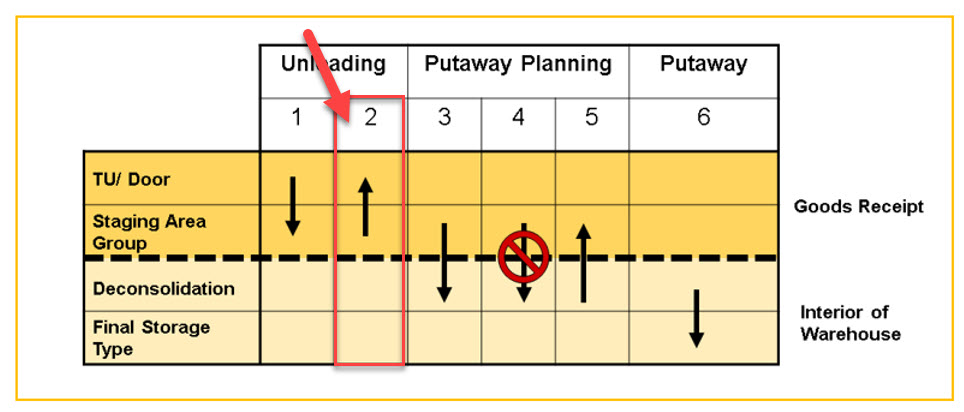

Graphic #1: An Inbound delivery has been created with respect to vendor PO, system is configured in such a way that Goods movement Bin is Door Bin with Unloading, Planned Putaway and Putaway status as not Started. In this example, lets move the HU from Door Bin (Goods Movement Bin) to Staging Area as highlighted below:

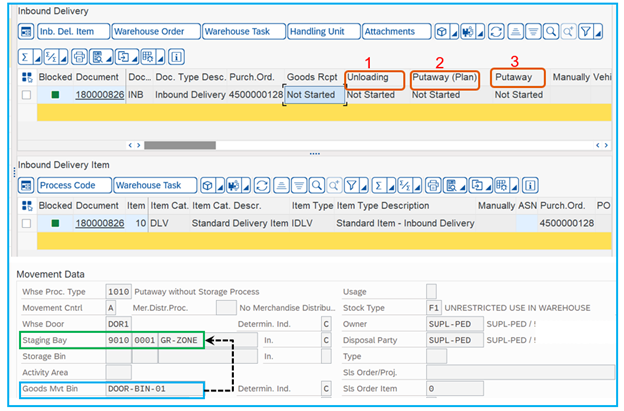

The Inbound delivery is packed into below HU as Highlighted.

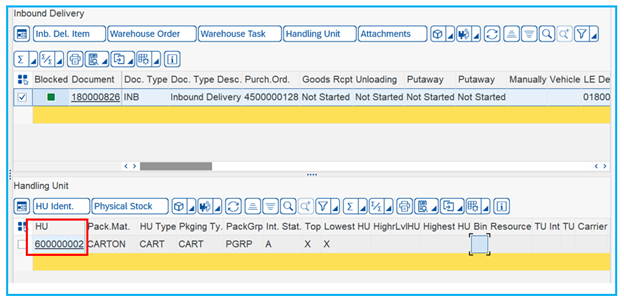

The following rules apply for the status Unloading:

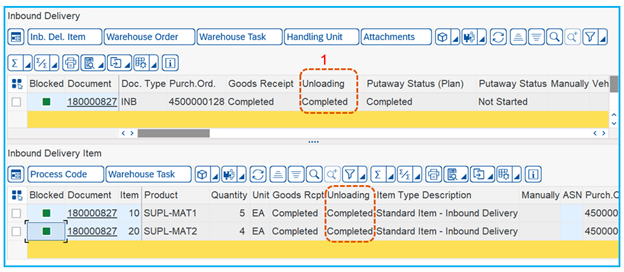

If an HU WT or a product WT with source HU is confirmed that is moving from a door to a staging area group, EWM sets the status Unloading in the inbound delivery (see number 1 in the graphic).

Before WT confirmation: Unloading Not started

After WT Confirmation: Unloading Status is completed

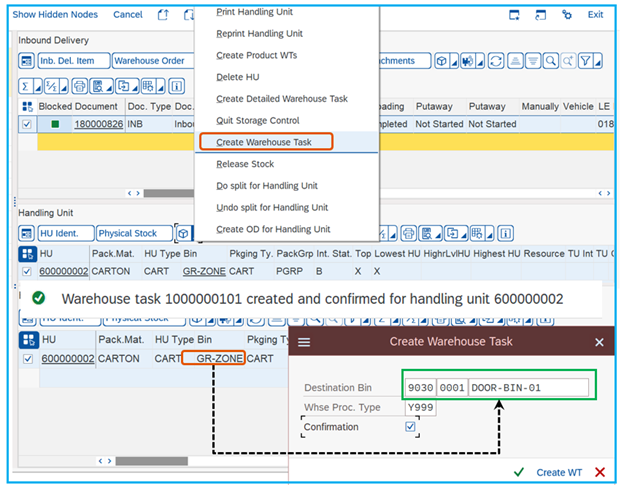

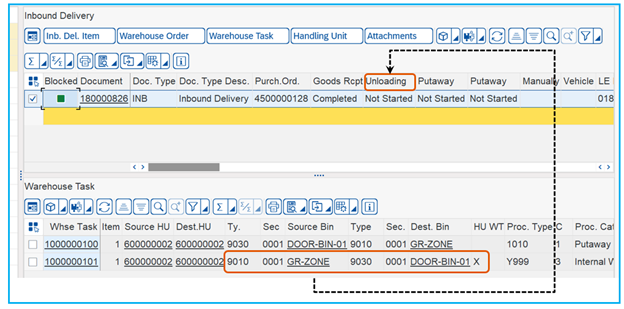

Graphic #2: If an HU WT is confirmed that is moving from a staging area group to a door or a TU in a reverse direction, EWM resets the status Unloading in the inbound delivery (see number 2 in the graphic).

Before WT confirmation: Unloading Not started

After HU WT confirmation: Unloading status gets reset = Not Started.

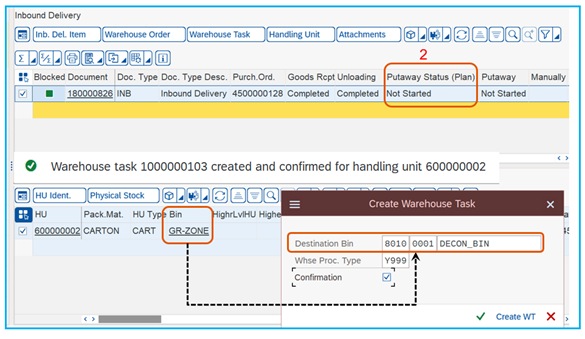

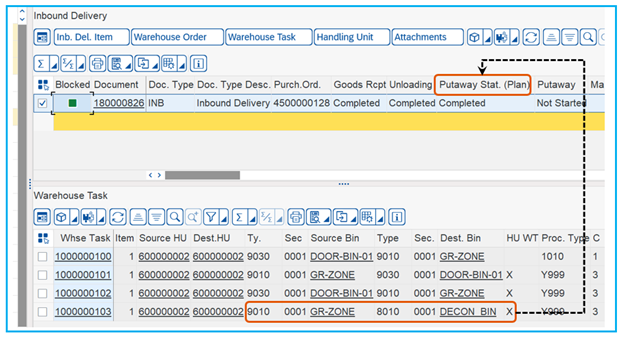

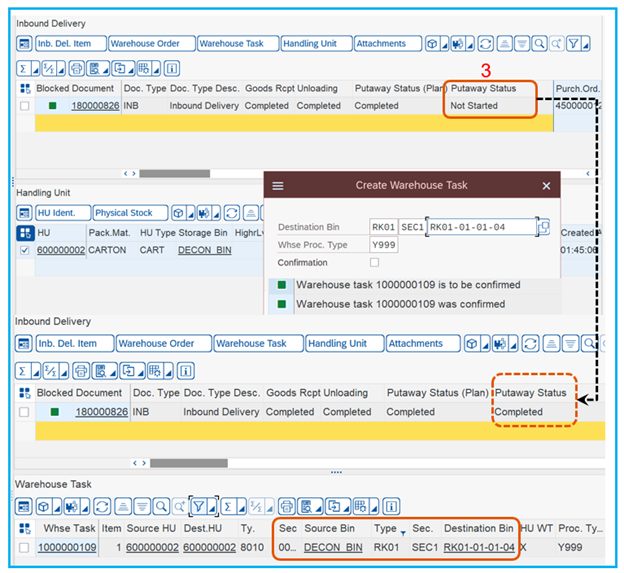

Graphic 3: If an HU WT is generated manually or by system that is moving from goods receipt to the interior of the warehouse, EWM sets the status Putaway Planning in the inbound delivery.

Before Confirmation HU WT- Planned Putaway= Not started

After HU WT confirmation, Planned Putaway Status= Completed

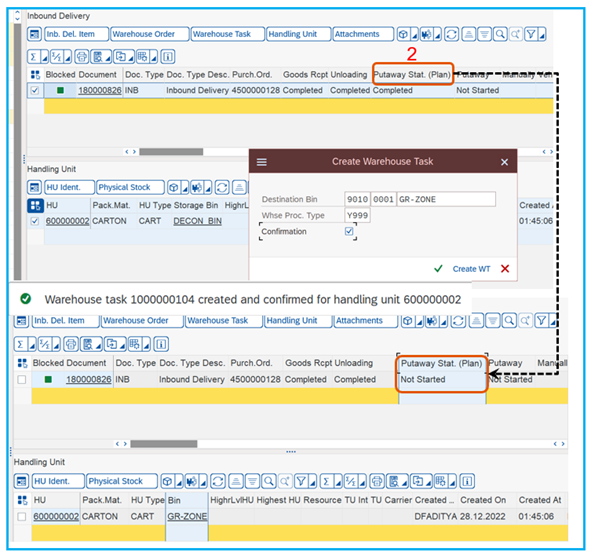

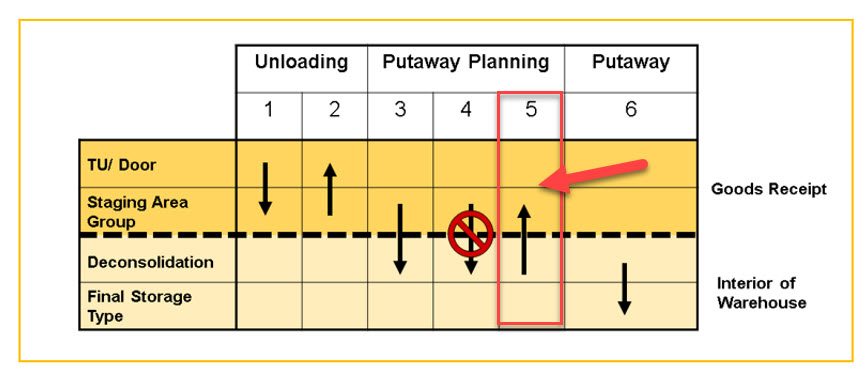

Graphic 5: If an HU WT is confirmed that is moving from the interior of the warehouse to goods receipt as below, EWM resets the status Putaway Planning in the inbound delivery.

Putaway Planned status changes from ‘’Completed to Not started after moving from Interior of Warehouse (Decon Zone) to Staging Area

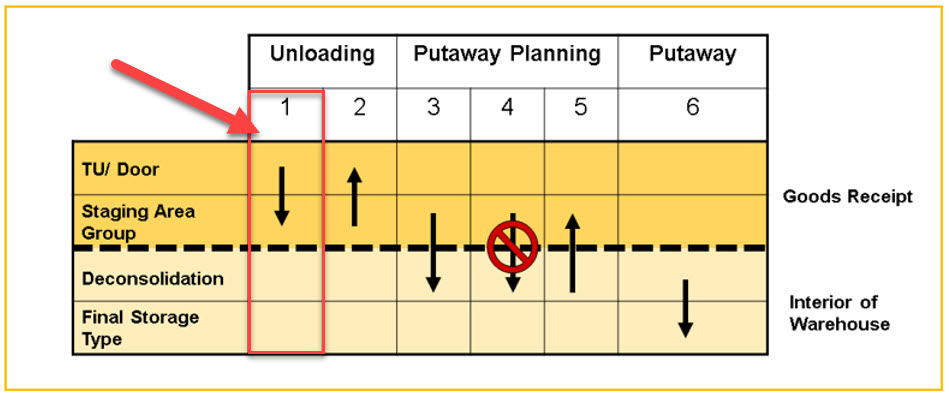

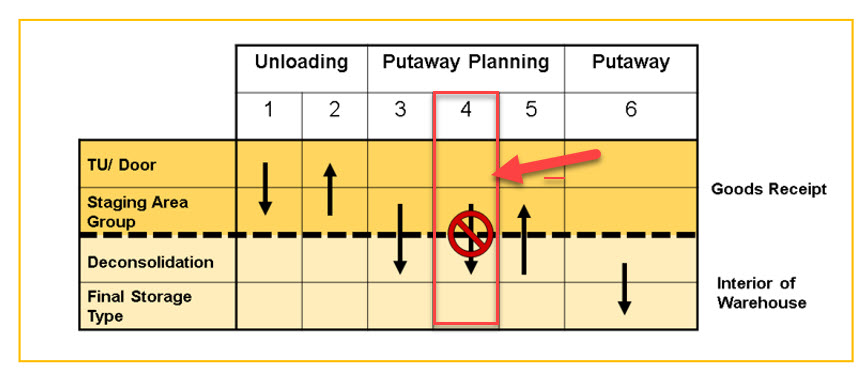

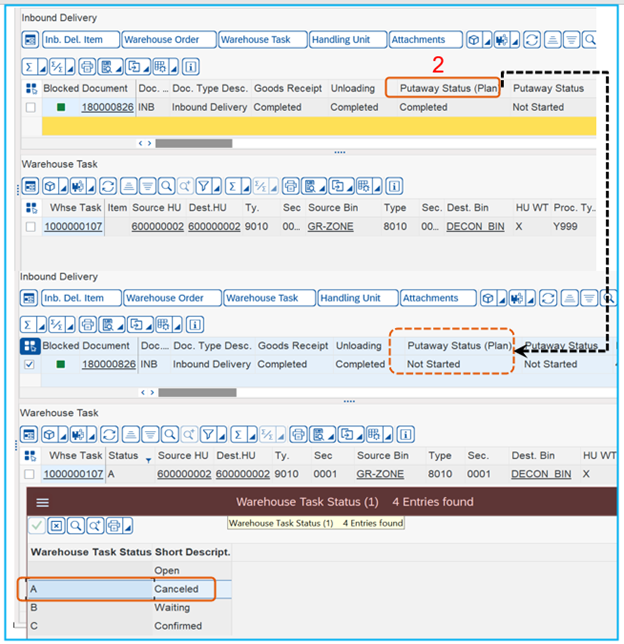

Graphic 4: If an HU WT is cancelled that is moving from goods receipt to the interior of the warehouse, EWM resets the status Putaway Planning in the inbound delivery.

After cancellation of HU WT( GR zone to Decon station), delivery status = Not Started

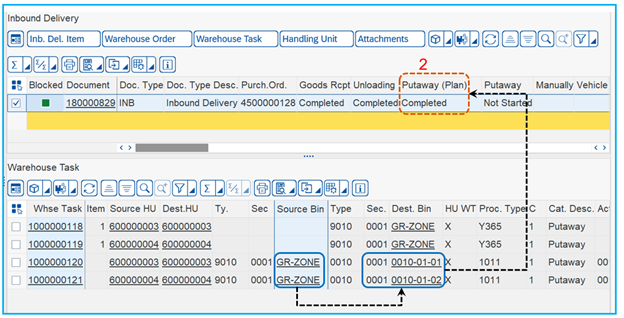

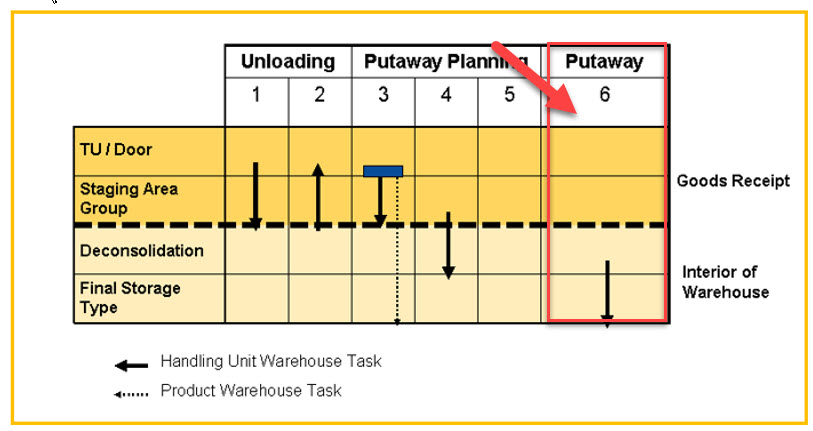

Graphic 6: Putaway Status:

If an HU WT is confirmed that contains the final storage type, EWM sets the status Putaway in the inbound delivery (see number 6 in the graphic).

Putaway status changes from Not Started to Completed when HU is moved from Interior of Warehouse to Final storage type.

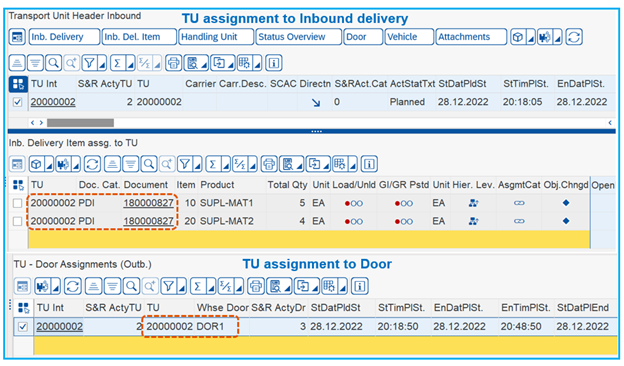

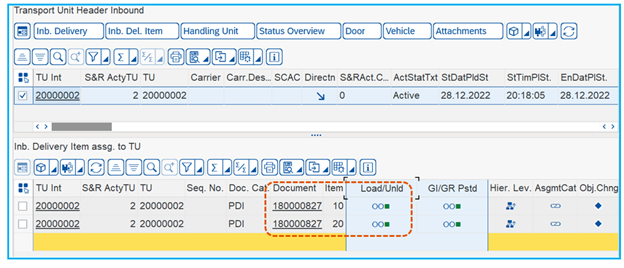

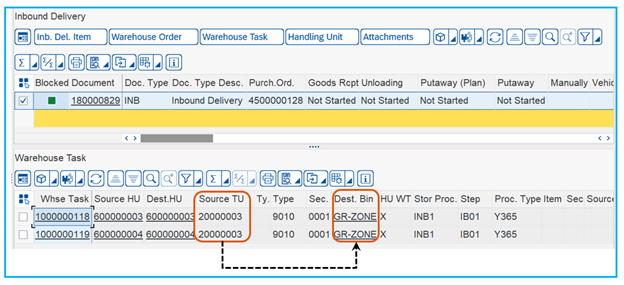

An Inbound delivery is created with 2 Items and corresponding TU is assigned to Inbound delivery as below. Transportation Unit( Trailer) is docked to Door( DOR1). The products are in unpacked form without HU.

Lets check the Inbound delivery status. Unloading status = Not Started

If a product WT for unpacked stock is confirmed that is located in a TU or storage bin at the door, EWM sets the status Unloading in the inbound delivery. A prerequisite for this is that the destination location in the product HU is not a TU, or that the destination storage type in the product WT is not a door

Graphic 1: Stock is moved from TU to staging area group.

Inbound delivery Unloading status changes from Not started to Completed. This works for Planned putaway status as well.

TU Inbound Delivery status

If you confirm a product WT that contains the final storage type, EWM sets the status Putaway in the inbound delivery. (Graphic 6)

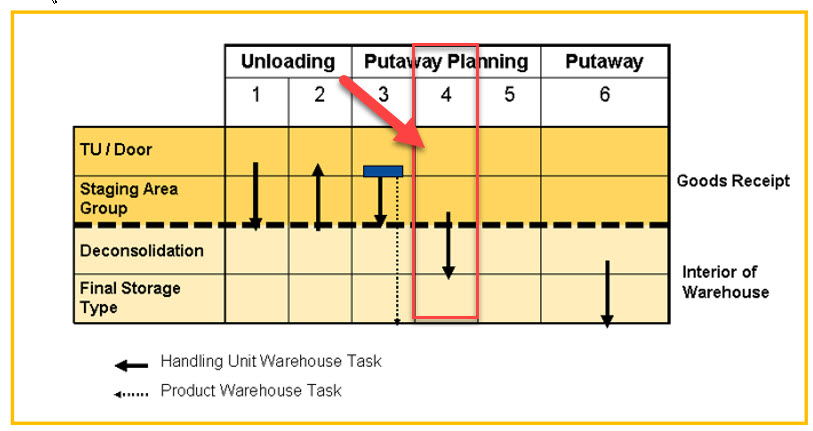

If an HU WT is confirmed that is moving from a door or TU to a staging area group, EWM sets the status Unloading in the inbound delivery (see number 1 in the graphic).

In below example, HU is moved from TU to staging area via POSC with unloading WT creation.

The unloading status gets reset when HU is moved from Staging area to TU or Door

If the system generate a product WT for putaway and an HU WT for unloading, EWM always sets the status Putaway Planning in the inbound delivery corresponding to the warehouse activities for the product WT. EWM uses the HU WT to update the status Unloading in the inbound delivery

Putaway Planning Status: If the system generate an HU WT into the interior of the warehouse(Deconsolidation Zone) and no product WT for putaway exists, EWM always sets the status Putaway Planning in the inbound delivery corresponding to the warehouse activities for the HU WT (see number 4 in the graphic).

Putaway Status: If you confirm a product WT that contains the final storage type, EWM sets the status Putaway in the inbound delivery corresponding to the product WT. If you confirm an HU WT that contains the final storage type, EWM sets the status Putaway in the inbound delivery corresponding to the HU WT. This means that, depending on which WT you confirm first, EWM sets the status Putaway in the inbound delivery with this WT (see number 6 in the graphic)

Summary

Now that we have finished, let’s revisit the concept. Extended Warehouse Management (EWM) updates the inbound delivery corresponding to the goods receipt activities. For the goods receipt process (GR process), EWM maps the warehouse with the goods receipt and interior of the warehouse areas. This allows EWM to determine the point in time from when a putaway is planned, that is, from when a warehouse activity exceeds the limit for the interior of the warehouse. The following information belongs to the goods receipt area:

- Transportation units (TUs)

- Storage bins at warehouse doors

- Staging area groups

All storage types that do not correspond to goods receipt belong to the interior of the warehouse area. For example:

- Work centers

- Identification points

- Final storage types

EWM updates the statuses Unloading, Putaway Planning and Putaway in the inbound delivery, corresponding to this warehouse mapping.