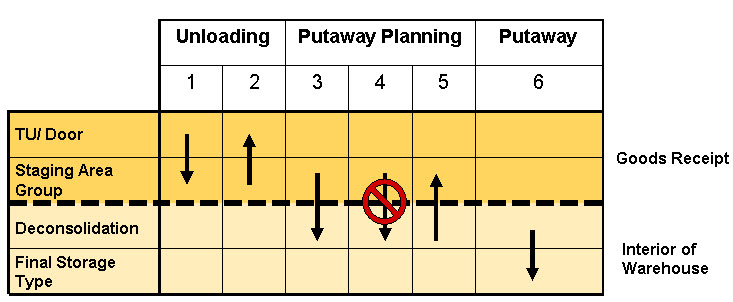

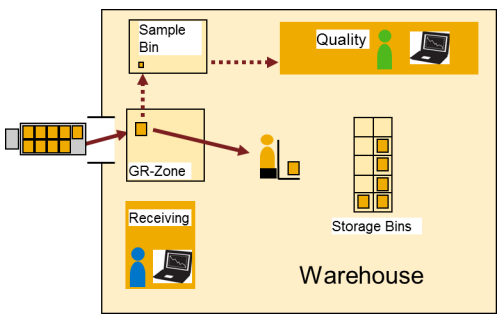

Extended Warehouse Management (EWM) updates the inbound delivery corresponding to the goods receipt activities. For the goods receipt process (GR process), EWM maps the warehouse with the goods receipt and interior of the warehouse areas.

Extended Warehouse Management

Configuring EWM SAP record inspection and usage decisions for the partial quantities of an inspection lot, when, for example, only some of the stock items in the inspection lot are of good quality.

SAP has provided tons of enhancements options in SAP EWM, however, this blog is written to explain the 3 most used enhancements in EWM implementation projects.

Waves are the grouping of warehouse request items and In EWM, you can group the warehouse request items (such as the ODO items) into waves to manage the process and optimize the warehouse processing.

Goods movement in the warehouse follows several steps to complete an inbound, outbound, or internal process; for this, SAP EWM uses storage control.

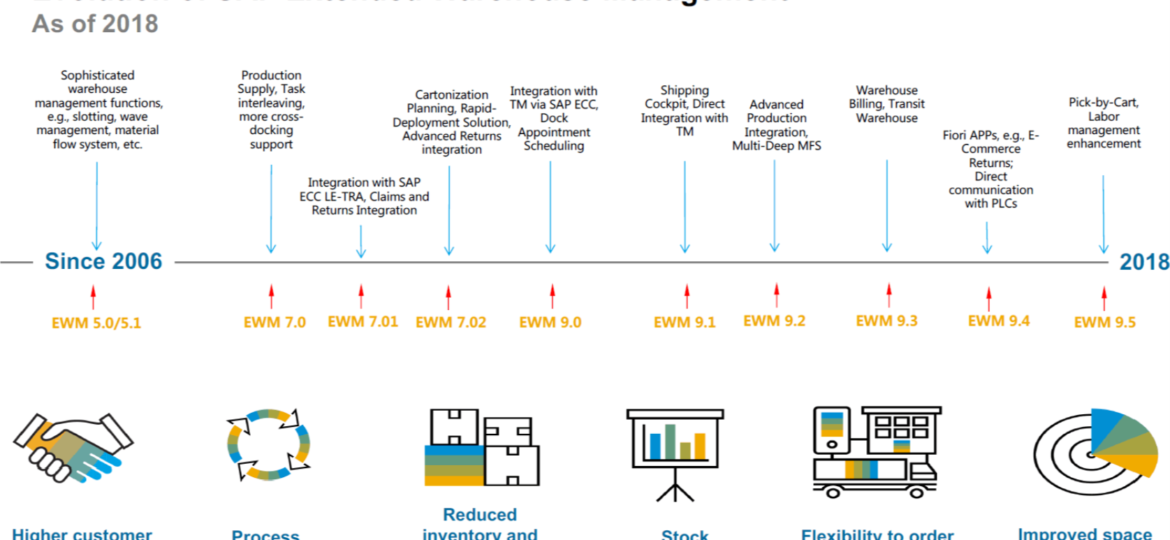

The increasing requirements toward a lean material flow to achieve reducing production costs and increasing quality, will get more and more important. And as such, it will become important to have an integrated IT Landscape. SAP EWM and Advanced Production Integration are steps toward optimal integration between production and logistics that ensures more reliability in deliveries and less need for stock in the Warehouse

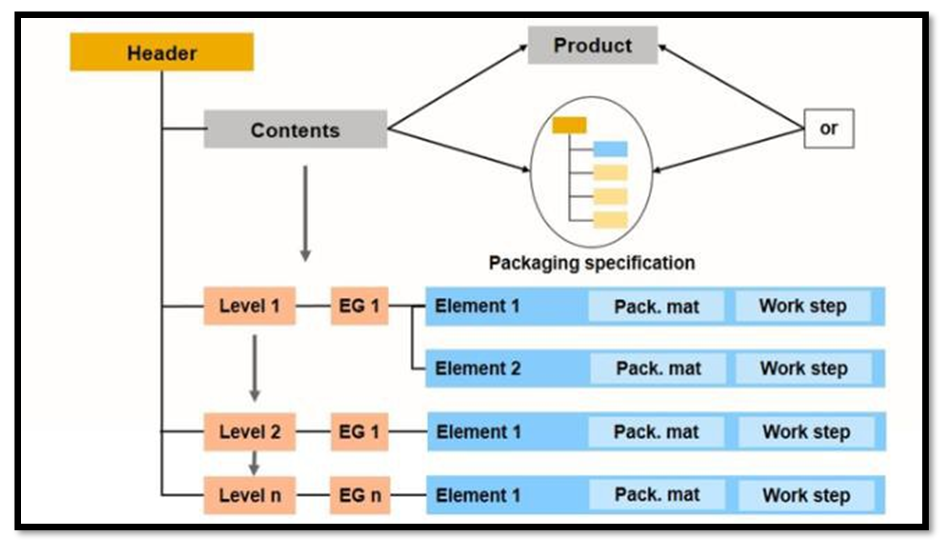

A packaging specification is master data. The packaging specification defines all the necessary packing levels for a product for example to put away or transport the product. For a product, a packaging specification mainly describes in which quantities you can pack the product into which packaging materials.

With SAP’s Extended Warehouse Management (EWM) on-premise or cloud deployment, you can manage high-volume warehouse operations and integrate complex supply chain logistics with your warehouse and distribution processes – delivering the ultimate in visibility and control. Optimize inventory tracking, cross-docking, distribution operations, multichannel fulfillment, and more – all in real time.