Shailesh Mishra is a SAP EWM Senior Consultant. Shailesh has deep Expertise in implementing and offering SAP EWM best practices solution and EWM deployment options on S/4 Hana embedded versions and decentral versions supporting various business verticals like Pharma, Food industry and Manufacturing. Cross module knowledge of SAP ERP logistics like SAP MM, SD and Production Planning. Strong technical knowledge of SAP ABAP. You can reach him at [email protected].

Shailesh Mishra is a SAP EWM Senior Consultant. Shailesh has deep Expertise in implementing and offering SAP EWM best practices solution and EWM deployment options on S/4 Hana embedded versions and decentral versions supporting various business verticals like Pharma, Food industry and Manufacturing. Cross module knowledge of SAP ERP logistics like SAP MM, SD and Production Planning. Strong technical knowledge of SAP ABAP. You can reach him at [email protected].

Back this month is Shailesh Mishra with another great Extended Warehouse Management (EWM) blog on Advanced Production Integration.

Advanced production integration allows the integration of supply of products to production and the receipt of products from production into warehouse in Extended Warehouse Management (EWM). It is integrated with the manufacturing order processing in SAP S/4HANA, but it allows to stage and consume the materials and receive the semi-finished products or finished products in EWM. This means it can process the warehouse execution for manufacturing orders that have been sent to EWM from SAP S/4HANA even if SAP S/4HANA is not available.

Some of the advantages of using Advanced Production Integration are listed below:

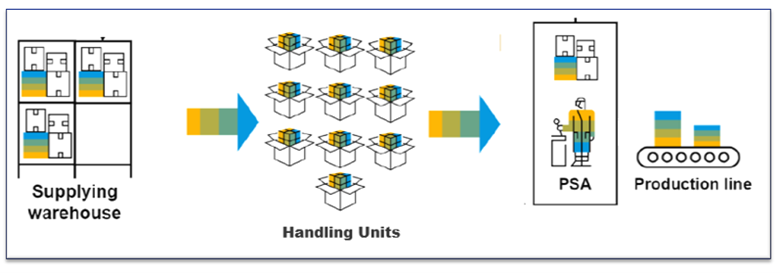

- Advanced production integration allows to plan the staging of products for production over a period, allowing to use the space on production supply area (PSA) more flexibly.

- Allows to receive packed products as soon as they arrive from the production line using radio frequency.

- This allows to synchronize the material flows between the warehouse and production promptly, which improves inventory visibility in EWM and in SAP S/4HANA.

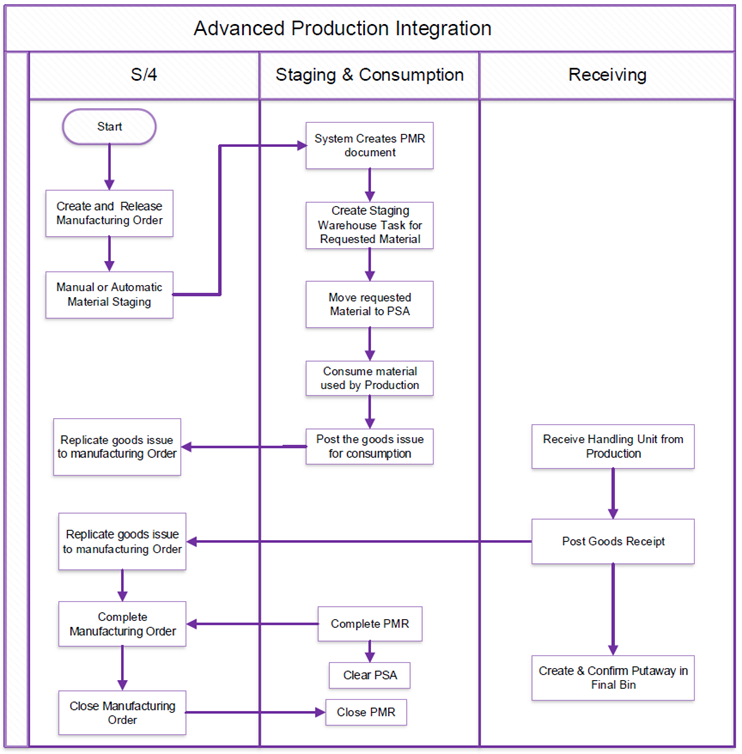

The following graphic shows the overall process of supply to production and receipt from production. It is followed by an explanation:

The production material request is a document containing all the Extended Warehouse Management-relevant data for a manufacturing order (a production order or process order). Production material request (Technical Replica of Manufacturing Order) is used for planning and monitoring the supply of products to production, and for the consumption of products by production, using advanced production integration.

The system creates a production material request when SAP S4 sends a message containing the required information from production. SAP S4 sends this message when the manufacturing order is released, and WM material staging is triggered, either automatically or in the Production Order Change transaction, either by choosing Function WM Material–> Staging Execute, or by clicking the WM Material Staging button.

If the manufacturing order is changed in SAP S4, the system updates the production material request in EWM for changes that are relevant for EWM, such as a changed quantity for staging.

When BOM components is supplied to production using advanced production integration, staging can be planned in a flexible manner, so that the products required are available when production needs them. Staging can be performed for the entire quantity of a product at once, or partial staging of quantities of the product at intervals over a period. This ensures that if space at production supply area (PSA) is limited, it is not blocked unnecessarily by products that are not required until later.

Products that have been staged for production but have not been used can be brought back into the warehouse in EWM, so they are available for use again.

EWM Single-order staging

The system creates a EWM task to move the product to the PSA for each production material request (PMR) item. Each warehouse task has a reference to a single PMR.

After the EWM task is confirmed, the stock on the PSA has a reference to the PMR item. So the stock is reserved for the reference PMR item. Only this PMR can be used to consume the stock. The reference to the PMR item for the stock can be manually removed.

This method allows to stage products for a specific PMR, or for a PMR that has special characteristics. For example, staging products from a special batch for one PMR.

EWM Cross-order staging

The system accumulates products from more than one PMR and creates a EWM task to move them to the PSA together. The EWM tasks have no reference to the PMR item.

After the EWM task is confirmed, the stock has no reference to a PMR item. Each PMR that has an item with the product can be used to consume the stock.

This is a flexible method which allows to stage products whether the product is required for one PMR in particular, or by several PMRs.

Let’s look at an example of cross-order staging — We can stage a pallet of a product for use by three production lines, where each line only needs a small amount of the product. All three PMRs can be used to consume the product from the pallet.

OK, lets use an S/4 System to replicate the above in EWM….

- Create the manufacturing order (production order or process order) in SAP S/4. Release the manufacturing order. In SAP EWM, the system automatically generates the expected goods receipt documents after order release. This functionality is available from 1909 Decentral EWM. From Embedded EWM, no EGR is created, EWM directly uses manufacturing order.

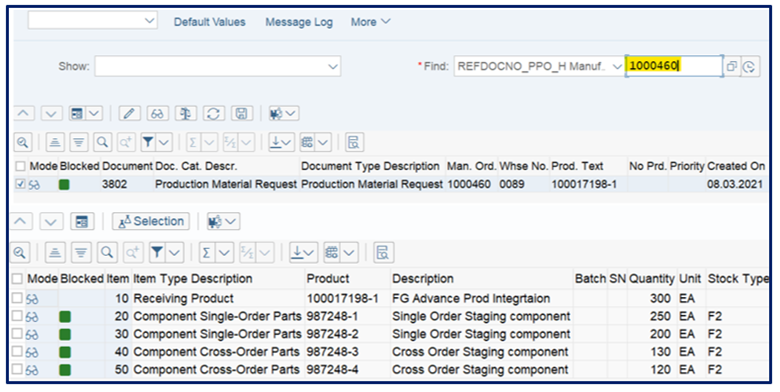

- Material staging is performed for the manufacturing order in S/4. The system creates a production material request (PMR) in SAP EWM, containing the information about the products needed by production and the quantities needed for the entire manufacturing order. The below PMR consists of 2 single order and 2 cross order staging components.

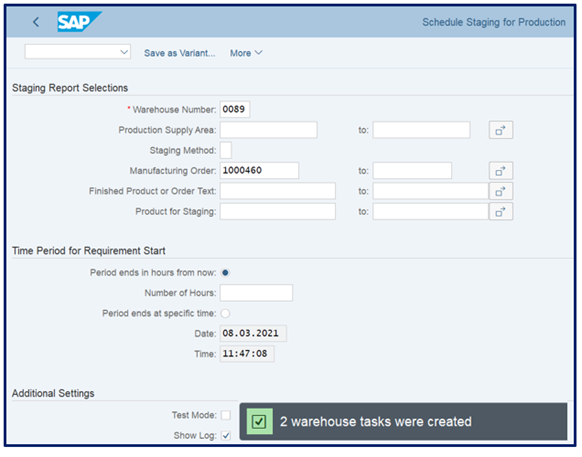

- Plan the staging of the products over the time period when they are required by creating the staging warehouse tasks. The system proposes a quantity to stage. This can be the entire quantity required by production or a smaller quantity to stage and replenish at intervals.

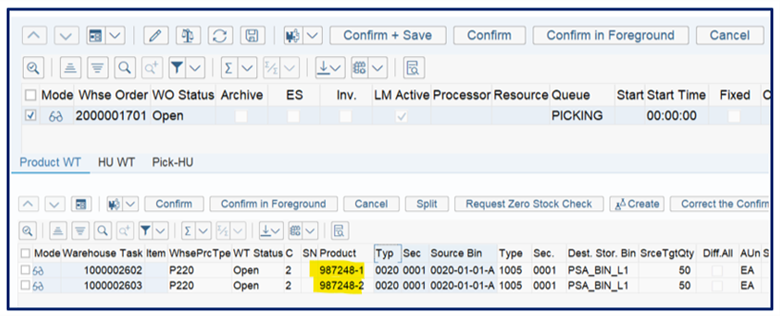

System created 2 Warehouse tasks for single order comp.

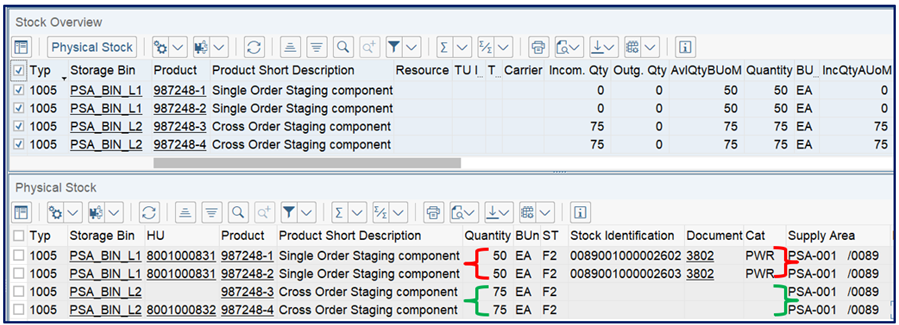

- Move the goods to the PSA and confirm the staging warehouse tasks. Product is now moved to production supply area as highlighted. Single order demarcated in red and cross order without PMR reference in green.

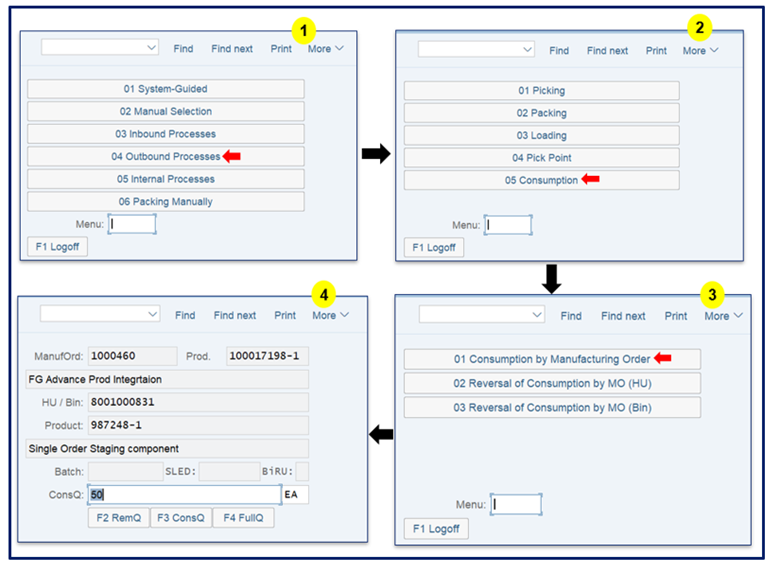

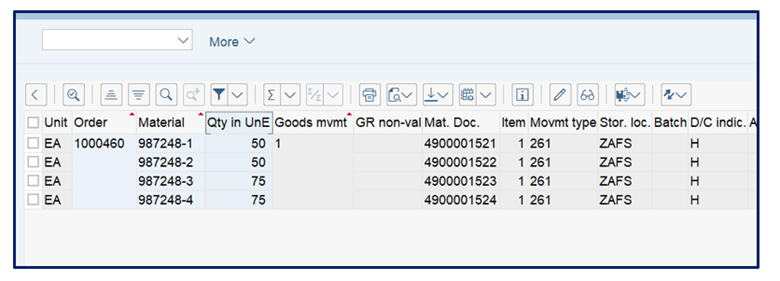

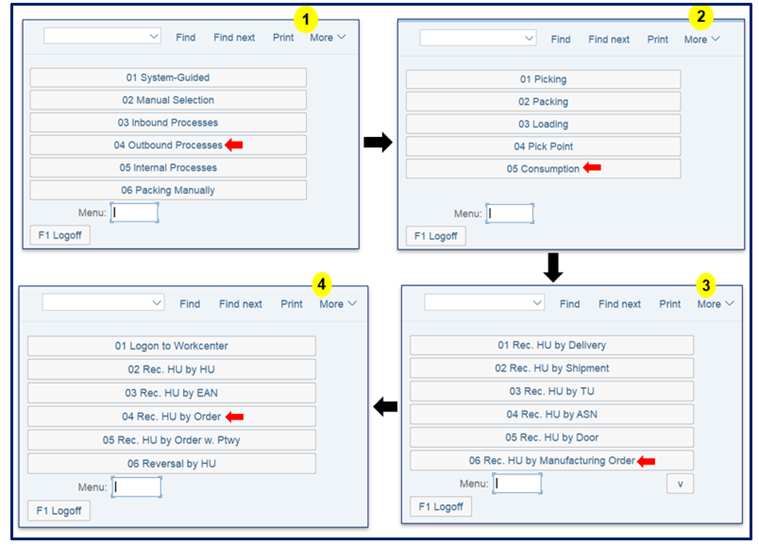

- As production consumes the goods, post the consumption in the system. Consumption posting can be trigger via RF or by Fiori App. The system posts goods issue for the consumed products and updates PMR in SAP EWM and the manufacturing order in SAP S4.

Scan the Handling unit number (from label of Packed Component) or scan the Bar code of PSA Bin. If product is not packed, scan the PSA Bin only

Complete all the scanning of HU to post the consumption. Consumption is successfully posted in EWM and in S/4 into manufacturing order.

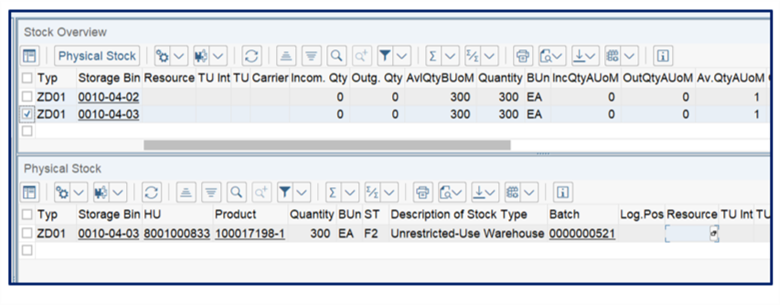

Create the warehouse tasks for put away, put away the products in the warehouse, and confirm the putaway tasks. Partially produced qty can be also packed into HU and moved into Warehouse AFS bin.

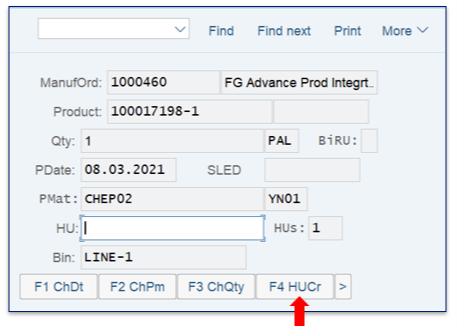

Now, post the quantity which is produced at Production Line by creating an HU.

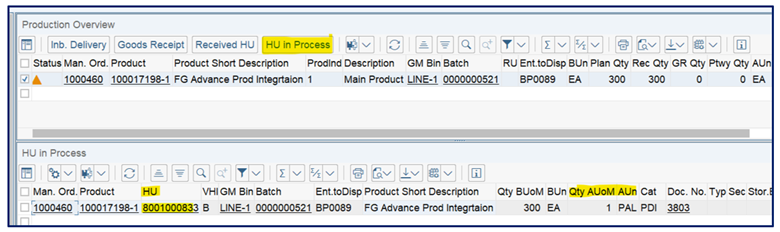

System created a handling unit from RF and it can be monitored for how much quantity is produced and packed, or waiting for putaway into Warehouse.

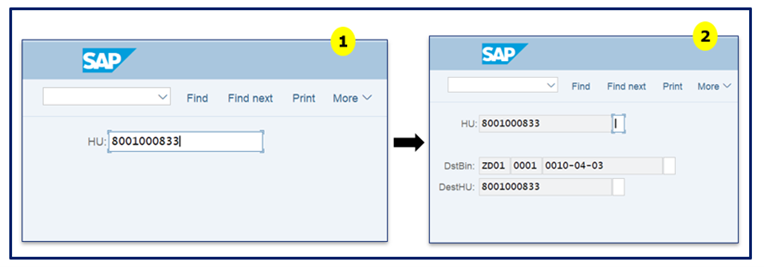

Now that we have a HU, we can perform the putaway of this HU from RF. Scan the source HU, destination and Destination HU.

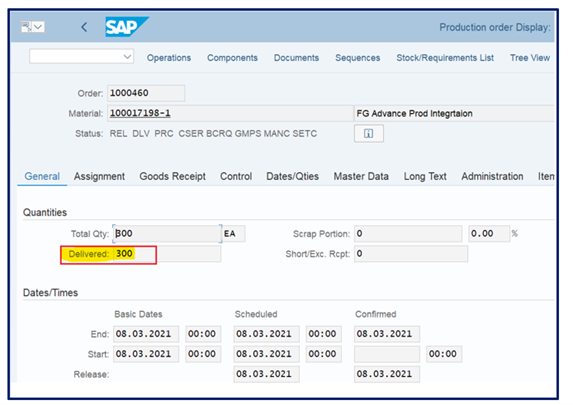

S/4 Production order is completed. The system automatically completes the PMR in SAP EWM.

Summary

The continuously increasing requirements within a lean material flow through the warehouse and production to achieve reducing production costs and increasing quality, it will get more and more important to have an integrative IT Landscape in the future. This landscape will not only include the communication between EWM and the used production integration model, it will also include material flow systems, like automated guided vehicles (AGV), as well as machine learning systems. Advanced Production Integration is a clean first step toward optimal integration between production and logistics that ensures more reliability in deliveries and less need for stock in the Warehouse.

With SAP’s Extended Warehouse Management (EWM) on-premise or cloud deployment, you can manage high-volume warehouse operations and integrate complex supply chain logistics with your warehouse and distribution processes – Optimize inventory tracking, cross-docking, distribution operations, multichannel fulfillment, and more – all in real time.