Shailesh Mishra is a SAP EWM Senior Consultant. Shailesh has deep Expertise in implementing and offering SAP EWM best practices solution and EWM deployment options on S/4 Hana embedded versions and decentral versions supporting various business verticals like Pharma, Food industry and Manufacturing. Cross module knowledge of SAP ERP logistics like SAP MM, SD and Production Planning. Strong technical knowledge of SAP ABAP. You can reach him at [email protected].

Shailesh Mishra is a SAP EWM Senior Consultant. Shailesh has deep Expertise in implementing and offering SAP EWM best practices solution and EWM deployment options on S/4 Hana embedded versions and decentral versions supporting various business verticals like Pharma, Food industry and Manufacturing. Cross module knowledge of SAP ERP logistics like SAP MM, SD and Production Planning. Strong technical knowledge of SAP ABAP. You can reach him at [email protected].

Back this month is Shailesh Mishra with another great Extended Warehouse Management (EWM) blog on some very important master data in EWM, packaging specifications and handling units.

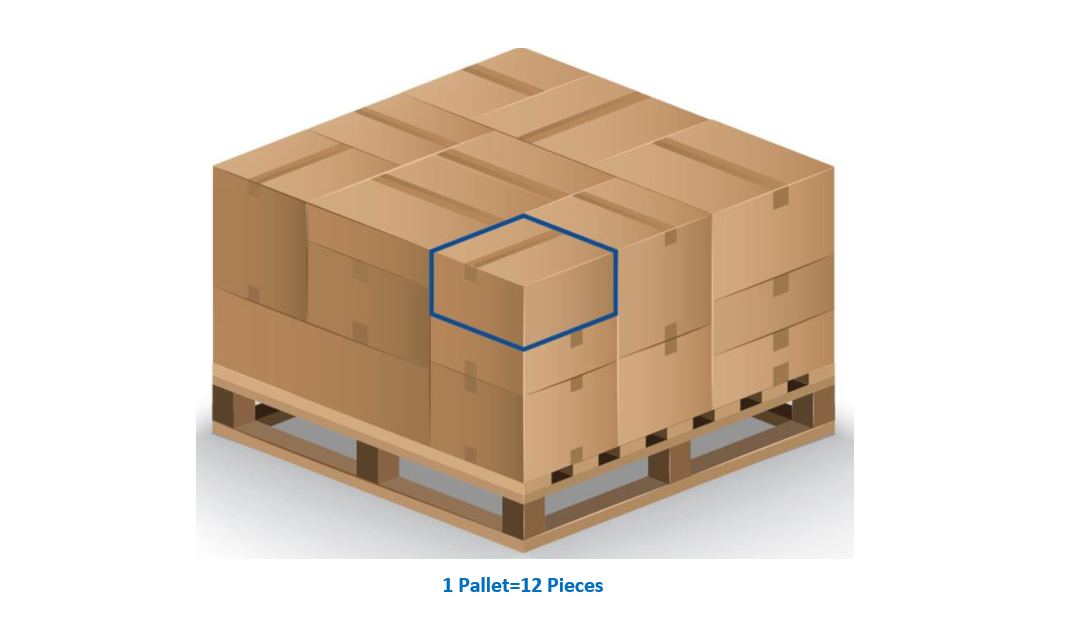

A simple usage of packaging specification in the warehouse is for palletization data.

Palletization data for a product specifies how the product is packed and put away.

For Example, in a warehouse, 12 Pieces of Product A is put on a pallet for A.

For this case: Create a Packaging specification for Product A with:

- Main packaging material of Pallet

- Contents of Product A

- Specify target quantity as 12

Note: If 36 pieces are delivered by vendor, the system uses the packaging specification to create 3 warehouse task for 12 pieces each, that is 3 Pallets of Product A

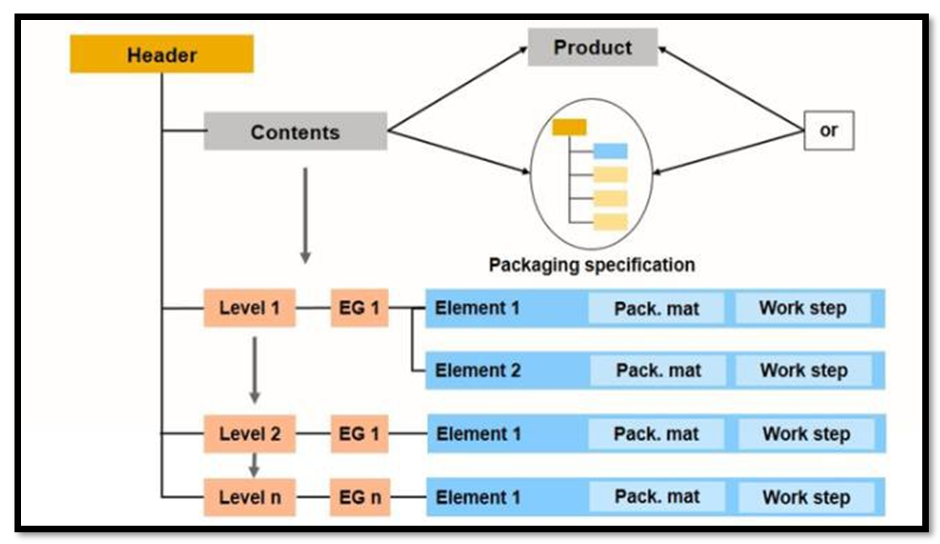

The packaging specification document defines the necessary packing levels for a product and the related packaging materials. The packaging includes the steps that must be performed during packing process.

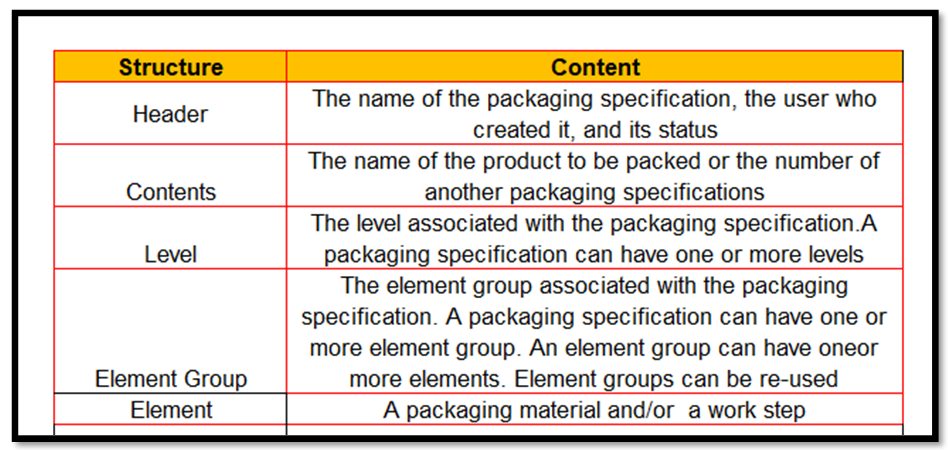

A packaging specification has a predefined structure as outlined in the following table.

A packaging material is a product that is used to pack products upon or to pack products in.

Packaging material must be defined as products, using fields that define the characteristics of the packaging such as

- Maximum packing weight

- Maximum volume

A work step is defined separately and is assigned to a packaging specification element. It is an instruction for a warehouse worker on how to apply a specific step of a packaging specification.

Packaging specifications are stored using the Integrated Products and Process Engineering(iPPE) data base engine.

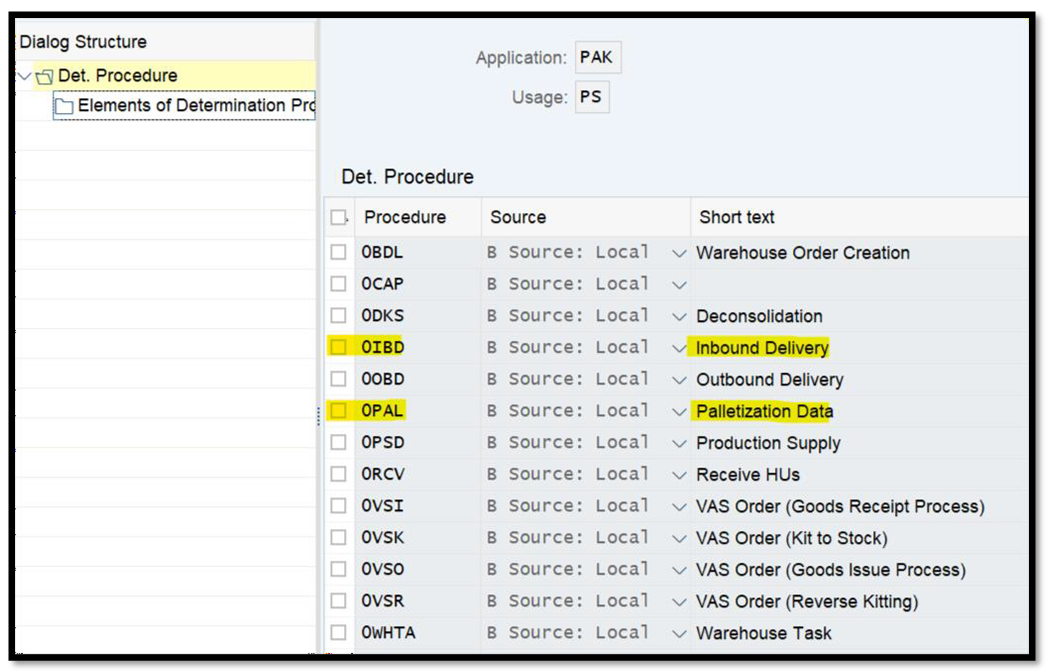

The determination of packaging specification is achieved using ‘’Condition Technique’’

Packaging specification determination is used in following processes.

- During automatic packing in goods receipt processing(Inbound Delivery)

- Determining packaging material in Warehouse order creation

- Determining packaging material in delivery processing

- Determining packaging material during consolidation

- Slotting

- During internal warehouse processes, for example, Palletization, determining unit of measure and so on…

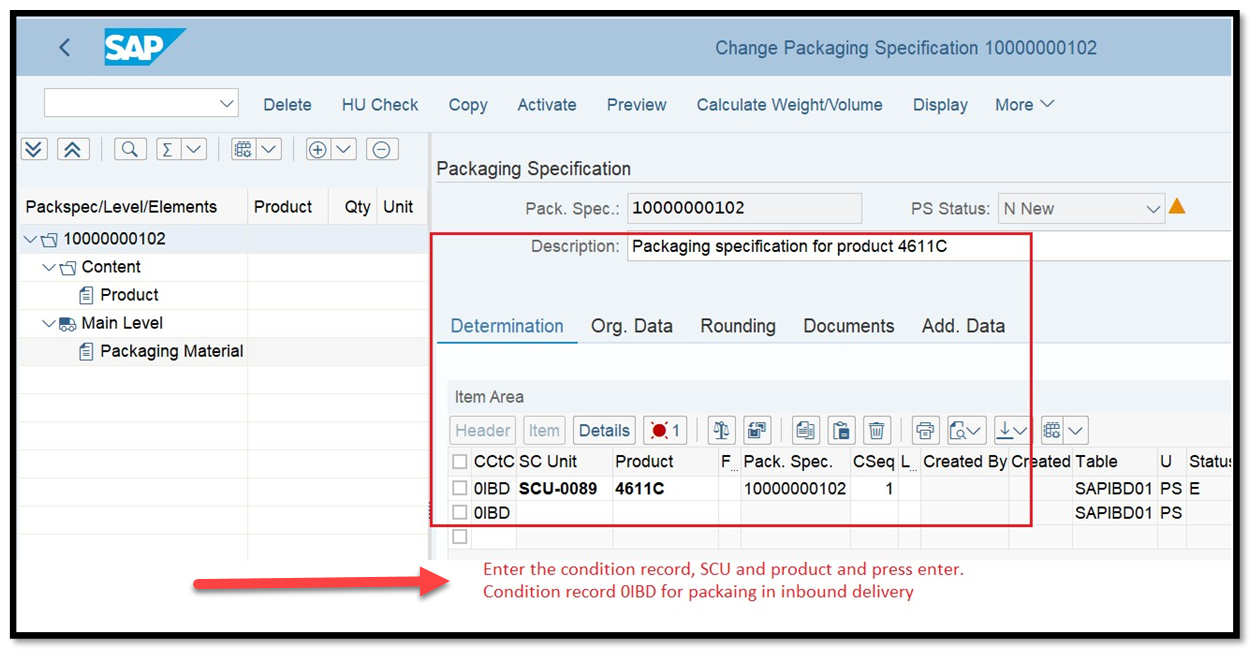

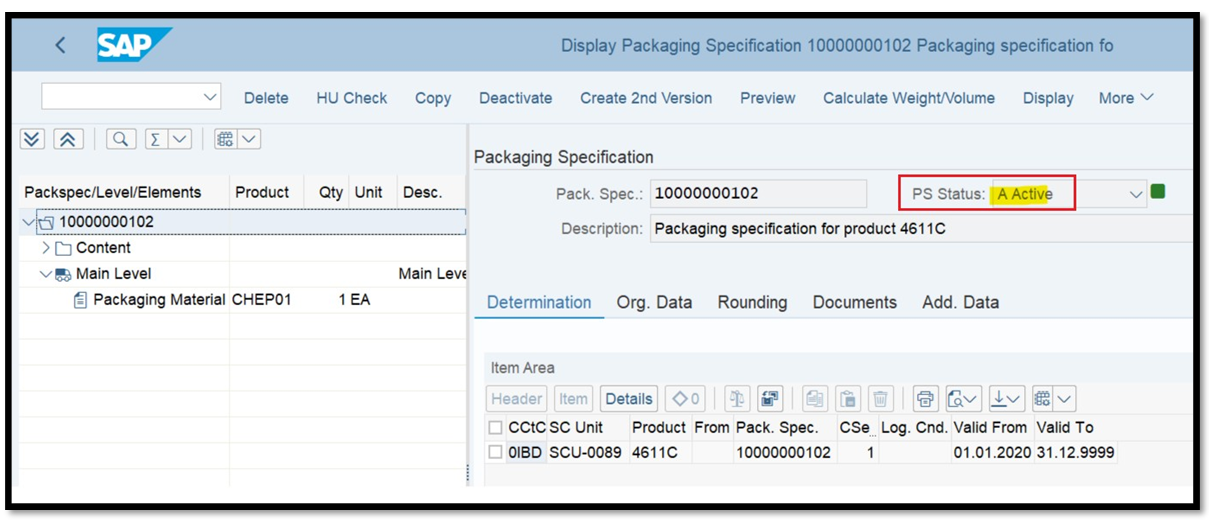

The packaging specification determination procedure, 0IBD (Inbound delivery)

All information that is relevant to a packed product (Example, Product, batch, serial number) are available with handling units.

The unique identification number for a handling unit number can be created from an internal number range or according to the industry standard EAN128, Serial Shipping Container Code (SSCC-18)

In SAP EWM, whether products need to be processed in handling units or not, depends on number of factors.

If the use of handling units is an enterprise-standard, then products are normally received, warehouse managed, and issued in handling units.

In warehouse where products are not generally managed in handling units form, certain SAP EWM processes require that products (received or issued) are packed into handling units. This may be only temporarily, for example, to facilitate the internal SAP EWM processes. In those cases, the put away process in SAP EWM requires the item to be packed in a handling unit.(HU)

Once the physical storage of that item is complete, the HU number can be removed from the items(On the system as well)

Handling units can only be stored in storage bins within the storage types that has been configured to allow handling units. In SAP EWM customizing of Storage types, the indicator of HUs allowed in storage type can be set as allowed or forbidden.

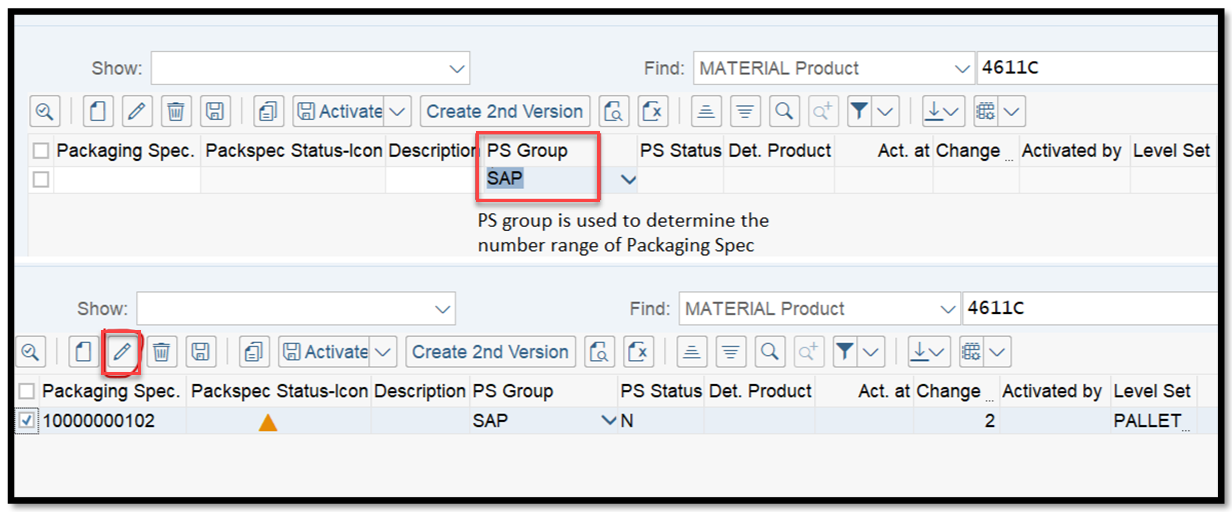

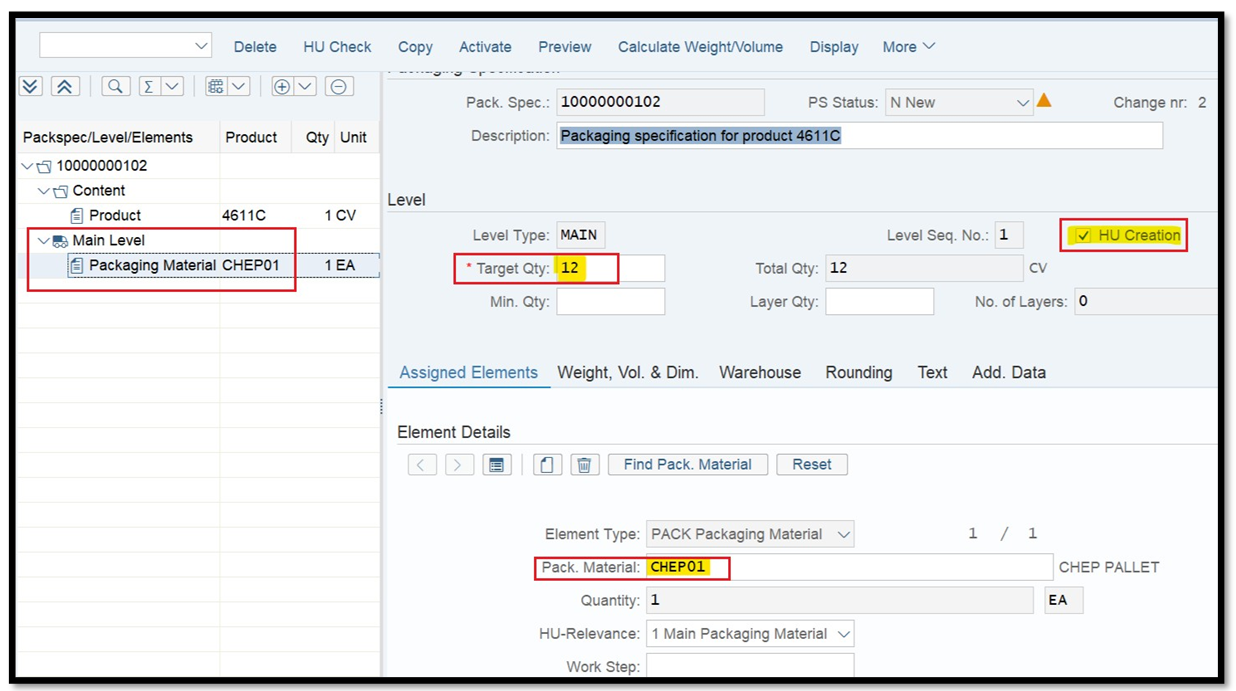

Go to transaction /SCWM/PACKSPEC – Maintain Packaging Specification.

- Select the product and PS

- Enter the required details in the next screen as mentioned below

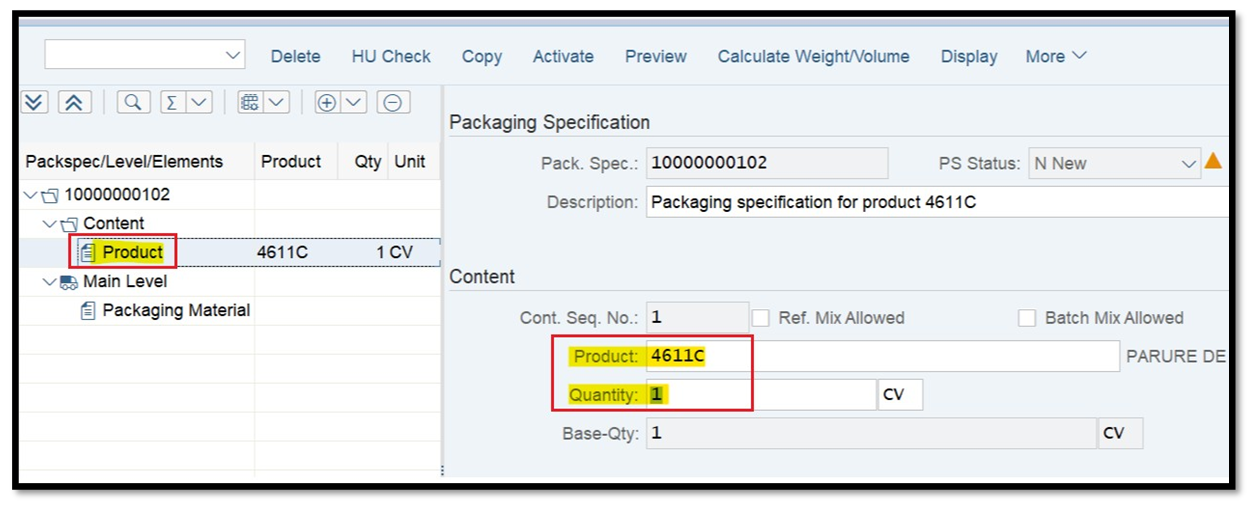

- Click on the product in left side bar. Enter the product, the base quantity

- Now, click on packaging material. Specify how many pieces can be packed in 1 Pallet

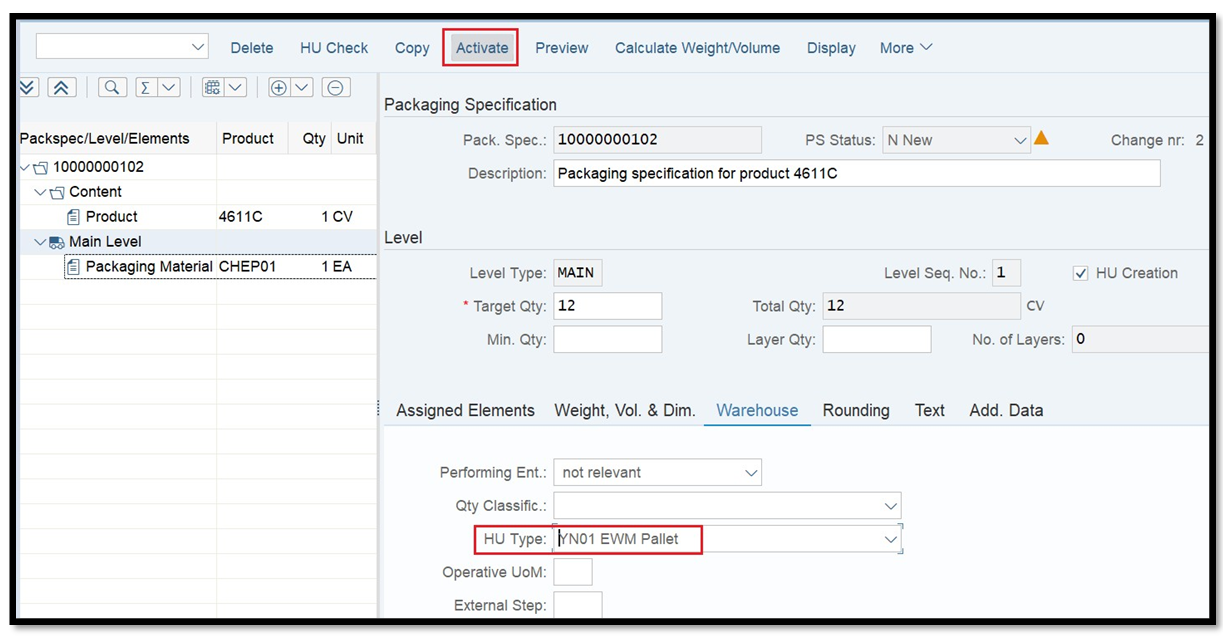

It is also important to check HU type in warehouse tab of packaging specification because we are packing 12 Boxes in 1 Pallet , HU type. Click on Activate and then Save.

If you have activated and save the packaging specification, you can no longer able to edit post activation.

Other condition record can also be used that depends on the requirement of business process at which point of time, packaging specification determination needs to happen.

If Business needs packaging specification determination at time of creation of Warehouse task, 0PAL determination procedure, needs to be maintained in packaging specification.

Summary

Remember, A packaging specification is master data. The packaging specification defines all the necessary packing levels for a product for example to put away or transport the product. For a product, a packaging specification mainly describes in which quantities you can pack the product into which packaging materials.

With SAP’s Extended Warehouse Management (EWM) on-premise or cloud deployment, you can manage high-volume warehouse operations and integrate complex supply chain logistics with your warehouse and distribution processes – Optimize inventory tracking, cross-docking, distribution operations, multichannel fulfillment, and more – all in real time.