Shailesh Mishra is a SAP EWM Senior Consultant. Shailesh has deep Expertise in implementing and offering SAP EWM best practices solution and EWM deployment options on S/4 Hana embedded versions and decentral versions supporting various business verticals like Pharma, Food industry and Manufacturing. Cross module knowledge of SAP ERP logistics like SAP MM, SD and Production Planning. Strong technical knowledge of SAP ABAP. You can reach him at [email protected].

Shailesh Mishra is a SAP EWM Senior Consultant. Shailesh has deep Expertise in implementing and offering SAP EWM best practices solution and EWM deployment options on S/4 Hana embedded versions and decentral versions supporting various business verticals like Pharma, Food industry and Manufacturing. Cross module knowledge of SAP ERP logistics like SAP MM, SD and Production Planning. Strong technical knowledge of SAP ABAP. You can reach him at [email protected].

Back this month is Shailesh Mishra with another great Extended Warehouse Management (EWM) blog on the three inevitable enhancements in EWM SAP implementations.

In most of complex EWM SAP implementations, the business requirement cannot be fully mapped with SAP standard solutions, and hence it becomes inevitable to use SAP EWM Badis to hook customer specific enhancements and put the own code to meet the business requirements. This blog is written on my personal experience with 5 EWM SAP implementations, where in every project, it becomes viable to use these enhancements to alter EWM SAP standard behavior and enhance to cater customer needs

SAP has provided tons of enhancements options in EWM SAP to enhance user-defined fields or to hook customer specific enhancements for a required EWM SAP business process, however, this blog is written to explain, the 3 most used enhancements in EWM SAP implementation projects.

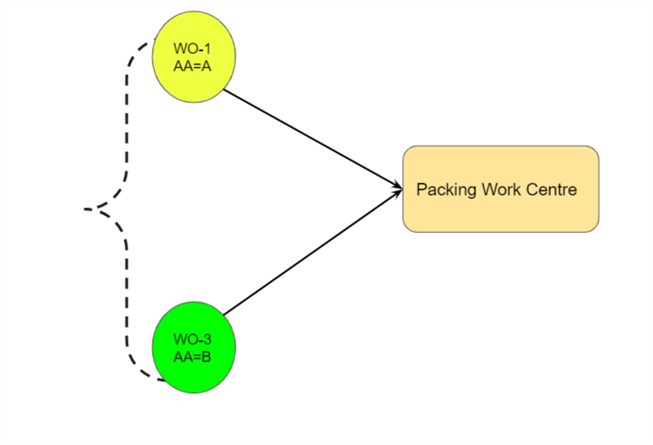

In case of deliveries which consist of multiple warehouse orders the first started warehouse order causes an update in priority of all linked EWM SAP warehouse orders for this delivery.

Requirement for this Enhancement:

If one warehouse order is started earlier than its planned latest starting date and time, then related warehouse order should also start earlier so that in example all items that are needed to be packed together into a shipping Handling Unit (HU) arrive approximately at the same time at the packing work center. Therefore the packing step can start and also finish earlier than planned.

Example: warehouse order A is started in activity area “bulk”. Automatically the second warehouse order B (same delivery) is raised in priority for activity area “rack” so that both warehouse orders have a better chance to arrive simultaneously at the packing work center.

Solution:

A BAdI example implementation /SCWM/EI_CORE_POST_CONS_WHO for BAdI definition /SCWM/EX_CORE_CO_POST in enhancement spot /SCWM/ES_CORE_CO is delivered by SAP. The BAdI example implementation implements following logic:

”EWM SAP Warehouse orders for one delivery are consolidated by latest starting date and time. If one warehouse order is started earlier than planned the latest starting date and time of the other warehouse orders related to the delivery get updated.”

- The system checks the planned completion time of the EWM warehouse order that started earlier. Upon confirmation of its first warehouse task the planned completion time of the warehouse order is re-calculated based on its planned duration. The completion time serves as reference completion time and the planned duration as reference duration for related warehouse orders.

- The latest starting date and time of related warehouse orders is calculated based on the reference completion time minus the planned duration of the warehouse order.

- If the resulting latest starting time is in the future it gets rounded according to the configuration setting for resource management. If it is in the past the latest starting time is set to the current time.

Requirement for this Enhancement:

Reverse goods issue posting for an individual EWM SAP Outbound Delivery Order, Outbound Delivery or Handling Unit (HU) that has been posted together with other deliveries or HUs.

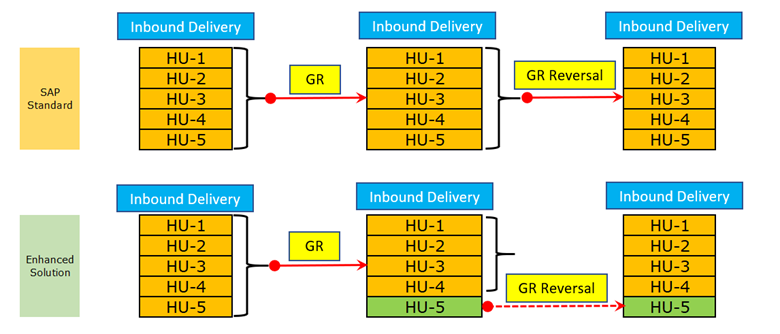

Whenever the goods receipt is performed, the reversal can only be done for all the stocks that were posted together. In this case there is no possibility to revert one HU for example that shouldn’t be posted due to any reason.

Reverse goods receipt only possible for all the stocks together that were posted in the same document.

Solution:

SAP has provided BAdI /SCWM/EX_DLV_GM

Method: /SCWM/IF_EX_DLV_GM_PROCESS~CHECK_GR_TYPE in order change the flag of goods receipt type to check goods movements for the delivery (goods receipt, posting change, goods issue, reversal) prior to posting. By setting error messages, business can cancel the posting.

In addition, the BAdI can be used to set a flag in order to determine the goods receipt mode. With the basic setting, which is implemented in the fall back class, the original goods receipt process is used. By changing the flag in a custom implementation, the goods receipt mode can be changed in order to receipt on handling unit level, one by one. Instead of calling the goods movement for each handling units, with this solution the goods receipt will be done in one step, but each handling unit will get own goods movement document.

This will help to reverse the goods receipt individually for the required handling unit later on.

Note: This is the same enactment used by SAP in customer connection program related to : IR 220314,Reverse GI of single deliveries.

Requirement for this Enhancement:

The request is to adapt existing inactive EWM SAP warehouse tasks (status ‘Waiting’), if an active warehouse task for the same source Handling Unit is cancelled.

In case the first active warehouse task is cancelled, the second warehouse task also should be cancelled.

Warehouse task in status ‘B’ (Waiting) cannot be confirmed. Therefore, the second warehouse task should be cancelled automatically, when the first warehouse task is cancelled.

Standard SAP does not support this functionality till S/4 HANA 2021 version.

In case of cancellation of the active warehouse task, the inactive warehouse task remains in status ‘Waiting’. The new creation of the first warehouse task automatically created the second warehouse task, but both inactive tasks stay in status ‘waiting’.

Solution:

SAP has provided a Badi /SCWM/EI_CORE_POST_CANC_WT ,BAdI definition /SCWM/EX_CORE_CO_POST in enhancement spot /SCWM/ES_CORE_CO

An example implementation in class /SCWM/CL_EI_CORE_POST_CANC_WT is delivered and can be copied.

If the example class does not exist yet, business can also just create their own implementation of /SCWM/IF_EX_CORE_CO_POST~POST, with the coding of /SCWM/CL_EI_CORE_POST_CANC_WT, Method /SCWM/IF_EX_CORE_CO_POST~POST

Summary

EWM SAP is a highly flexible warehouse management solution. Numerous requirements of medium complexity can already be met by the vast functional scope and configure-ability of the standard provided software application. In case enhancements are necessary, they can often be achieved through BAdI implementations or by using specialized frameworks to realize adaptations. In this blog I have shown you 3 of the most used EWM SAP enhancements I have personally implemented in all my implementations.