Shailesh Mishra is a SAP EWM Senior Consultant. Shailesh has deep Expertise in implementing and offering SAP EWM best practices solution and EWM deployment options on S/4 Hana embedded versions and decentral versions supporting various business verticals like Pharma, Food industry and Manufacturing. Cross module knowledge of SAP ERP logistics like SAP MM, SD and Production Planning. Strong technical knowledge of SAP ABAP. You can reach him at [email protected].

Shailesh Mishra is a SAP EWM Senior Consultant. Shailesh has deep Expertise in implementing and offering SAP EWM best practices solution and EWM deployment options on S/4 Hana embedded versions and decentral versions supporting various business verticals like Pharma, Food industry and Manufacturing. Cross module knowledge of SAP ERP logistics like SAP MM, SD and Production Planning. Strong technical knowledge of SAP ABAP. You can reach him at [email protected].

Back this month to close out the year is Shailesh Mishra with another great Extended Warehouse Management (EWM) blog on Partial Inspection on one Handling Unit.

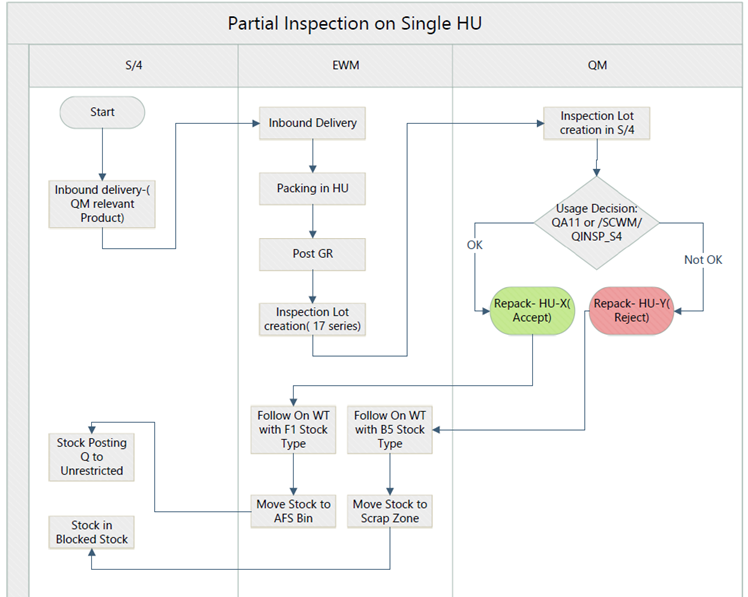

Conception: – With SAP S/4 HANA (both embedded ewm vs decentralized ewm), this feature enables to record inspection results and usage decisions for the partial quantities of an inspection lot, when, for example, only some of the stock items in the inspection lot are of good quality. The EWM SAP system then creates a partial lot and triggers follow-up actions for the partial lot quantities.

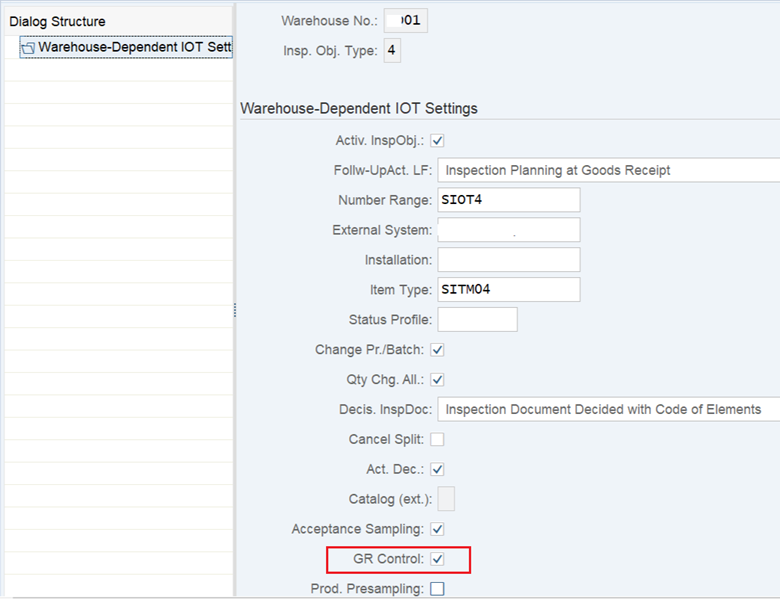

Context: – EWM SAP is integrated with the SAP QM component using inspection lot origin 17 (see above). When maintaining usage decisions for partial quantities, below business process can be performed.

- Split quantities further than how they are split when received into the warehouse (which can be, for example, by pallet or handling unit (HU)).

- Record a quantity difference between the quantity expected and the quantity received.

- Change product numbers or batch numbers.

- Assign serial numbers for partial quantities.

- Manually trigger follow-up actions.

- Repack partial quantities into new destination HUs and close HUs.

- Print HU labels.

- Change the layout of the Stock Items to Be Inspected screen into a vertical or horizontal split screen for improved visibility with many stocks.

So, how do we accomplish this? Lets get into the steps below

- Maintain usage decision codes in Customizing for Quality Management under Quality Inspection–> Inspection Lot Completion–> Edit Code Groups and Codes for Usage Decisions.

- Maintain code sets for decisions for full quantities (inspection lots) and code sets for decisions for partial quantities (partial lots) in Customizing for Quality Management under Quality Inspection–> Inspection Lot Completion–> Edit Selected Sets for Usage Decisions.

- Assign the code sets for your warehouse in Customizing for Quality Management under Basic Settings –> Maintain Settings at Plant Level.

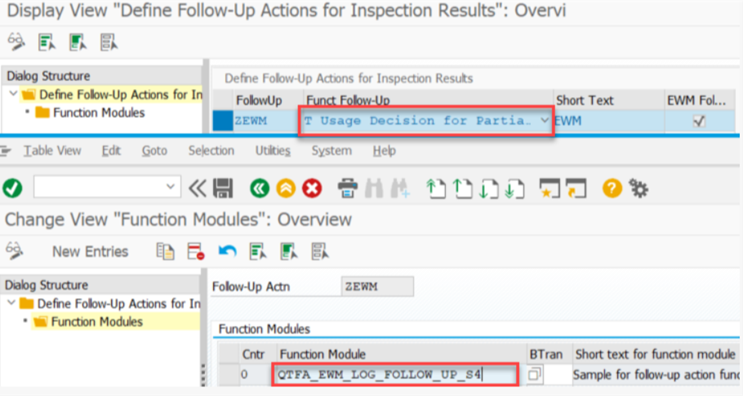

- Maintain follow-up actions for usage decisions and indicate that they are EWM follow-up actions in Customizing for Extended Warehouse Management under Cross Process Settings Quality Management–> Inspection Results–> Maintain Follow-Up Actions.

SAP delivers predefined follow-up actions for usage decisions as follows:

- Inspection lot

- EWM_A:Putaway to Final Storage Bin

- EWM_R: Putaway to Blocked Stock Area

- Partial lot

- EWM_AP:Putaway to Final Storage Bin (Partial Quantity)

- EWM_RP:Putaway to Blocked Stock Area (Partial Quantity)

Note-Use proper function (Permissible Follow-Up Action for EWM Function) for the follow-up action:

| Function Module | ‘Function Follow-Up’ (Permissible Follow-Up Action for Function) |

| QFOA_EWM_LOG_FOLLOW_UP_S4 | ‘L Usage Decision for Inspection Lot’ |

| QTFA_EWM_LOG_FOLLOW_UP_S4 | ‘T Usage Decision for Partial Lot’ |

Step by Step Configuration:

- Assign functions modules to the follow-up actions in Customizing for Extended Warehouse Management under Cross-Process Settings–> Quality Management–> Inspection Results–> Maintain Follow-Up Actions as follows:

- Function module QFOA_EWM_LOG_FOLLOW_UP_S4for usage decisions for full quantities (inspection lots)

- Function module QTFA_EWM_LOG_FOLLOW_UP_S4for usage decisions for partial quantities (partial lots)

2. If business wants to create destination handling units (HUs) for inspected goods or print HU labels for destination HUs, do the following:

-

-

- Define a quality inspection work center in Customizing for Extended Warehouse Management under Master Data–> Work Center.

-

When defining this work center, specify a work center layout for transaction type Quality Inspection and count.

b. Assign the quality inspection work center (that you defined previously) as the default work center in Customizing for Extended Warehouse Management under Cross Process Settings–> Quality Management–> Inspection Results –>Assign Default Work Center for Inspections.

Master Data required:

Inspection Rules: Use inspection rules to determine whether a delivery item or stock item is inspection relevant. An inspection rule consists of properties and arguments. The inspection relevance of a delivery item or stock item is determined based on the properties. The arguments specify the details of the inspection, for example, inspection type, location-independent stock type, or process step performed in the warehouse.

Use: The following options are available for defining the inspection setup:

From the material master

Maintain the inspection type and its attributes on the Quality Management tab page of the material master by choosing the Insp. Setup button and assign the inspection type maintained in the inspection rule and specify the inspection attributes. One must activate the material and inspection type combination so that the system can process inspection lots for this material and inspection type.

From the inspection rule

Maintain the complete inspection setup within the arguments of the inspection rule. There is no need to also maintain the inspection setup in the material master if inspection rule is used

Prerequisites

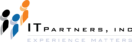

Specify whether the inspection lot setup data originates from the material master or from the inspection rule in Customizing for Extended Warehouse Management under–> Cross-Process Settings–> Quality Management–> Basics–> Warehouse-Dependent Activation of Inspection Object Type.

If the inspection lot setup originates from the material master, you must create a generic inspection rule to start the inspection process for all materials.

Create inspection rules on the launchpad Rule (transaction /SCWM/QRSETUP).

Maintain the properties and the arguments of the inspection rule. You must maintain an inspection type of inspection lot origin 17.

1) Create a purchase order and corresponding Inbound delivery in S/4 system. Ensure all necessary SAP QM related master data are maintained in S/4.

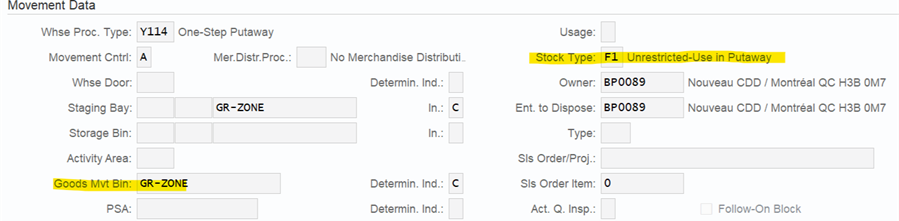

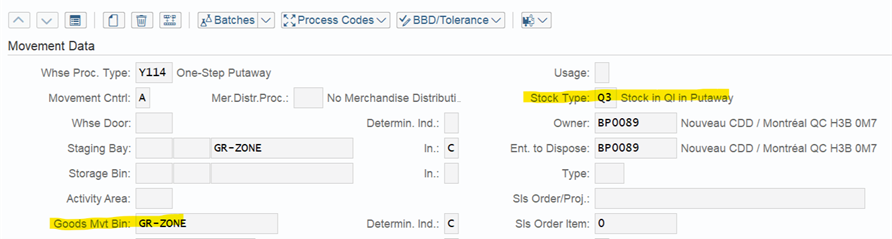

Before GR:

After GR: Stock type changed from F1 to Q3

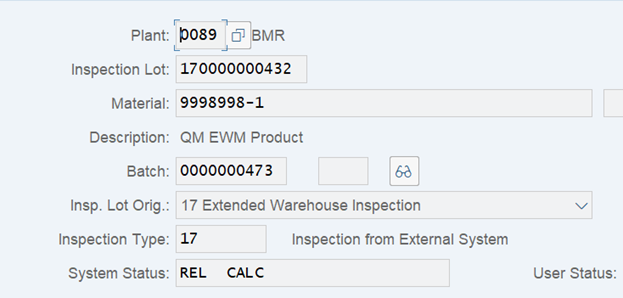

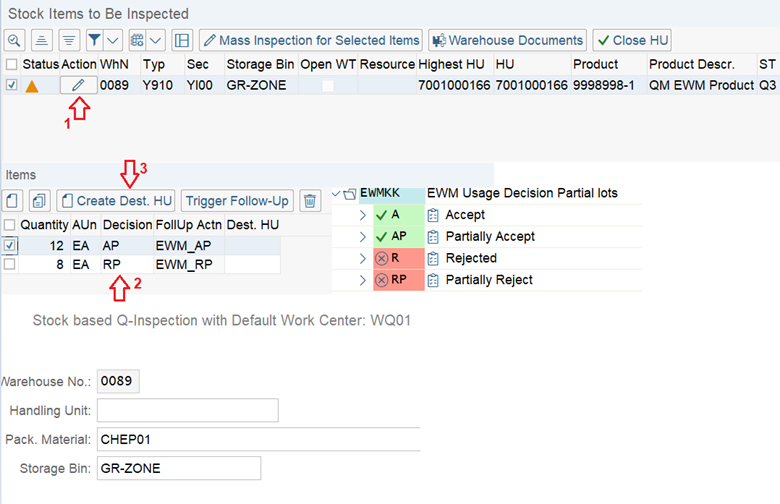

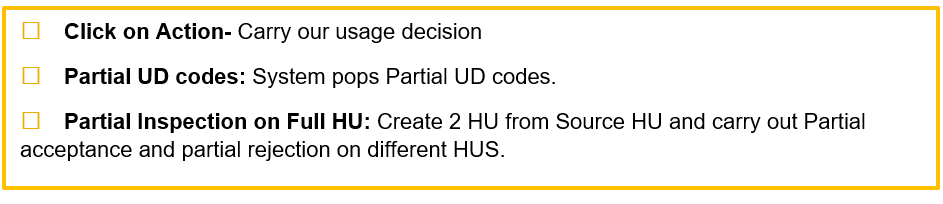

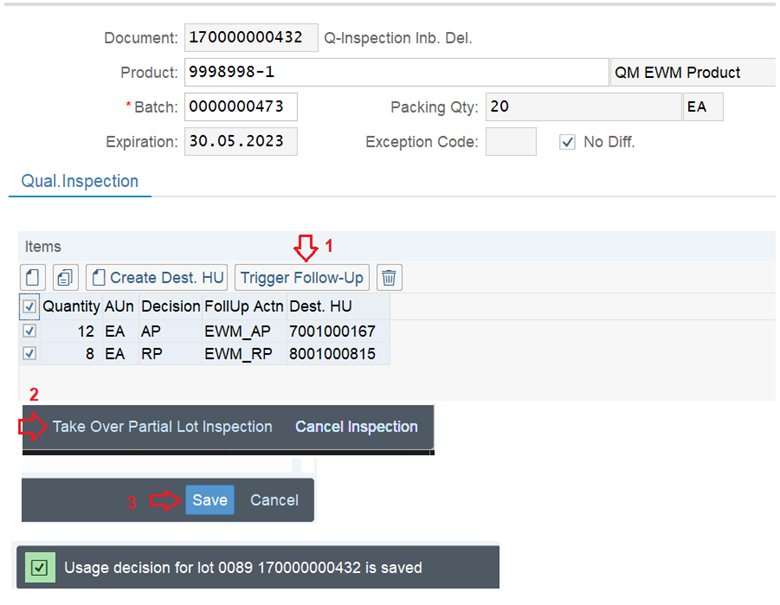

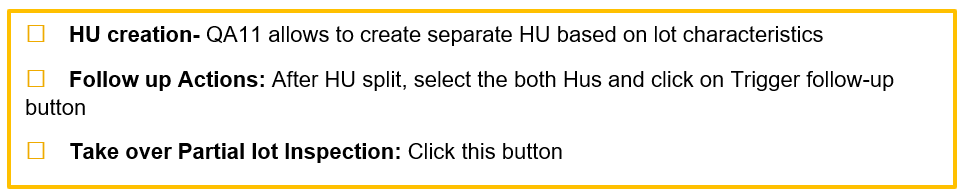

2) QA11 with Product, Batch and click on EWM inspection tab

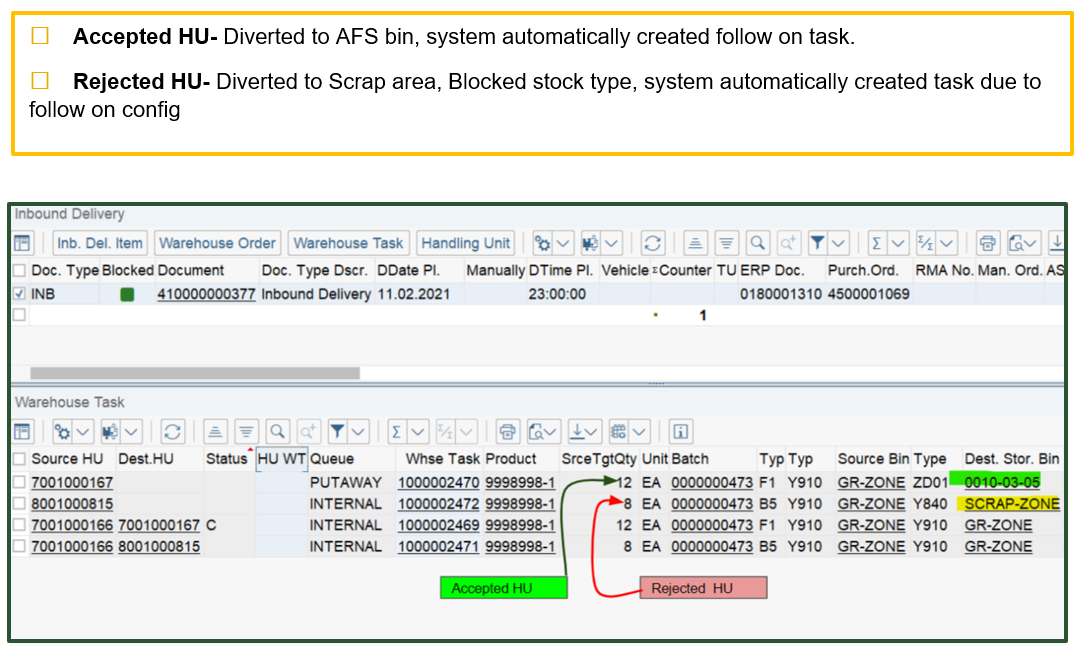

A detailed EWM SAP inspection screen opens which allows to perform multiple function from this screen. For this example, we have taken Partial UD which UD codes as AP( Partially Accept) and RP( Partially Reject)

Monitor Screen

Summary

Summary

SAP Extended Warehouse Management (EWM SAP) is meant to provide a superior quality inspection (QM SAP) process for incoming and outgoing materials.

With that in mind, companies that are currently using integrations of SAP Warehouse Management (SAP WM ) and Quality Management (QM SAP) to manage the quality inspection process should consider implementing warehouse management with SAP EWM and using that in conjunction with QM for quality inspections. Note that in EWM SAP, the quality planning and quality inspection business processes are managed through the Quality Inspection Engine (QIE), which is an add-on to the SAP EWM system.

After an SAP Extended Warehouse Management implementation, the integrated WM-QM system is only needed to keep the master and transactions data consistent between EWM-QM. Proper integration is crucial, since EWM SAP is installed on a different system than SAP WM and QM.

Companies planning to implement or migrate to SAP S/4HANA will find that Extended Warehouse Management (EWM SAP) is native to S/4HANA, so integrating EWM SAP with Quality Management business processes is easier and faster.