Anthony Cecchini is the President and CTO of Information Technology Partners (ITP), an ERP technology consulting company headquartered now in Virginia, with offices in Herndon. ITP offers comprehensive planning, resource allocation, implementation, upgrade, and training assistance to companies. Anthony has over 20 years of experience in SAP business process analysis and SAP systems integration. ITP is an Appian, Pegasystems, and UIPath Low-code and RPA Value Added Service Partner. You can reach him at [email protected].

Anthony Cecchini is the President and CTO of Information Technology Partners (ITP), an ERP technology consulting company headquartered now in Virginia, with offices in Herndon. ITP offers comprehensive planning, resource allocation, implementation, upgrade, and training assistance to companies. Anthony has over 20 years of experience in SAP business process analysis and SAP systems integration. ITP is an Appian, Pegasystems, and UIPath Low-code and RPA Value Added Service Partner. You can reach him at [email protected].

Everything nowadays is revolutionary to some extent. Irrespective of your feelings on ‘’revolution’’, all business sectors are in the midst of one. After all, almost everything in business is now changing to mirror the highest levels of customer experiences.

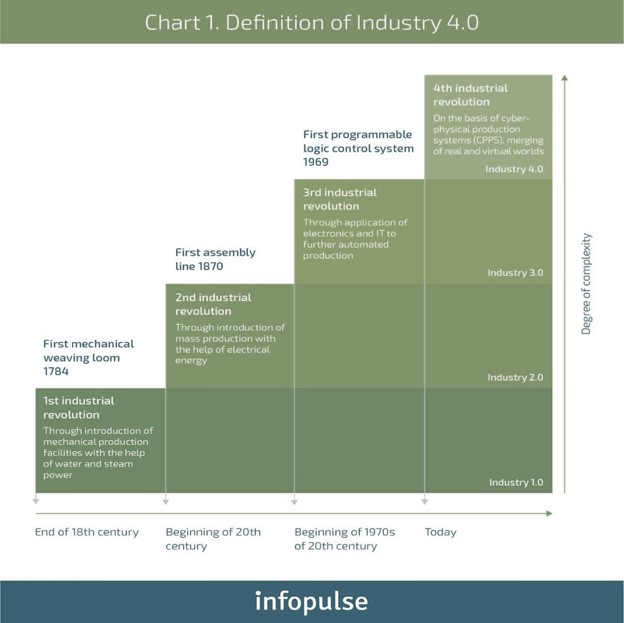

The 4th Industrial Revolution, sometimes called Industry 4.0, encompasses data automation and information exchange in different business areas. These include cognitive computing, the Internet of Things, cyber-physical systems, and cloud computing.

The following industrial revolution roadmap might help you understand the industrial revolution from the first to the current 4.0, so you can better appreciate what is in store:

Like the other revolutions that have changed manufacturing and business sectors in the past, Industry 4.0 is hinged on four fundamental principles. These include:

- Interoperability: your organization’s sensors, devices, and departments should communicate with each other via the IoP{ Internet of People} or IoT (Internet of Things).

- Information transparency: the information systems used for businesses nowadays should be capable of creating virtual copies of your physical data using sensor data.

- Technical assistance: informational assistance is one of the categories of technical assistance. Here, systems are designed to support humans through the aggregation of information visualization comprehensibly. This enables people to make informed decisions. The other technical assistance category requires physical systems that will support people in performing tasks that are too exhausting, unpleasant, or unsafe for humans.

- Decentralized decisions: cyber systems and machines are autonomous. They can in Industry 4.0 make decisions, perform tasks, and assign jobs without human intervention.

Is SAP in on this REVOLUTION?

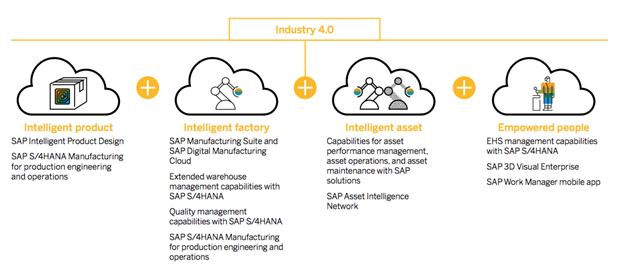

Yes!! SAP embraces Industry 4.0 holistically throughout a company to maximize the profit and avoid clashes between different departments. This means that a company can benefit from intelligent manufacturing in their factories with a seamlessly integrated supply chain execution.

The approach of SAP to Industry 4.0 combines three business concerns into one approach. These include:

- Focus on clients such that their needs form the basis of all your decisions.

- The reinvention of production through the use of intelligent processes and assets that will dynamically adapt to market changes and enable customization.

- Connection of your entire company and the coordination of logistics, services, and sales with your production process.

Intelligent Products

Customization is the most significant selling point for most companies nowadays. Few, if any, clients want to feel like they have something that everyone else can get. The intelligent products solution from SAP keeps your products and their processing steps in sync with manufacturing and engineering changes to sales configuration. Here are the three solutions under the Intelligent Products offering:

- Intelligent Product Design

This accelerates a company’s product innovation by giving your employees actionable live insights, needs-driven product development, and instant collaboration. This means that your product developers can work together with other departments in real-time. Moreover, it allows easy matching of your products’ processing with client specifications.

- Intelligent Manufacturing For Operations And Product Engineering

This solution improves your production planning while supporting designers during the complex assembly of your products. Intelligent manufacturing also accelerates the production process, enhances quality management, and ensures smooth information flow from your R&D teams to the manufacturing team.

- Internet of Things

The SAP IoT comprises reference architecture that essentially transforms sensor data into actionable insight. This offers companies specific abilities to handle critical IoT scenarios in their manufacturing logistics, supply, service management, and asset sectors. Some of the key features in this product include:

- Insight-driven process integration.

- Location-based services.

- Quick IoT application development.

- Choice of device management.

- IoT-enriched analytics.

Intelligent Factories

This solution centers on the creation of factories that have been optimized. The Intelligent Factories solution increases your processing floor visibility, manages operations with increased agility, and identifies the bottlenecks in your processes. These steps transform rigid production lines into flexible manufacturing cells. In so doing, you can shift your factory’s operations to mass customization from mass production. Some of the solutions under Intelligent Factories are:

- Extended Warehouse Management

This allows the digitization and acceleration of a warehouse’s operations. With the extended warehouse management feature, you can integrate the complex supply chain logistics with your distribution and storage processes to gain ultimate control and visibility in the warehouse. You can also optimize cross-docking, distribution, multi channel fulfillment, and inventory docking in real-time. In this regard, the feature reduces warehousing costs, improves services, and strengthens compliance. Moreover, it boosts transparency, accuracy, and productivity.

- Digital Manufacturing Cloud

The Digital Manufacturing Cloud is an MES {Manufacturing Execution System} of near real-time analytics and data. You can use it to analyze your business and manufacturing data, integrate systems, and fulfill manufacturing processes. This allows you to track manufacturing processes, improve report consistencies, and get consistent data.

- Edge Services

SAP’s Edge Services will deploy powerful microservices with strong offline capabilities into your system. The capabilities allow you to monitor factory actions, execute enterprise processes locally, and get domain-specific insights. You can also deploy, update, and execute your analytical models to predict incidents and find any anomalies in your operations. With Edge Services under SAP’s Intelligent Factories, you enjoy an improved speed of business processes and make decisions using real-time data.

The manufacturing feature similar to that offered in SAP under Industry 4.0’s Intelligent Product is also offered under Intelligent Factories.

Intelligent Assets

Assets are among the highest-cost elements in a business. Their frequent downtimes or breakdowns will take a significant toll on profits and consumer satisfaction. By integrating intelligence into the assets you manufacture or use, SAP allows you to capture then leverage data on your end-to-end supply chain. This data can be used to evaluate, optimize, and maintain company assets throughout their lifecycles right from their designs to decommission. This way, you can balance the profitability, health, and availability of your assets. Other than the IoT, the following are the features you can get with the Intelligent Assets solution by SAP’s Industry 4.0:

- Asset Performance Management

This enables asset managers, owners, and engineers to improve asset control while easing maintenance planning and enhancing its accuracy. With the Asset Performance Management solution, your employees can create an asset information management system and calculate the risk levels of different elements for your assets. The feature also allows them to identify potential failures and avoid or mitigate them. With these steps, the spending on asset maintenance and malfunction risks of machines remain low.

- Asset Intelligence Network

This feature allows relevant parties to share information about your machines on an asset intelligence repository. The feature collects and tracks data on machines then stores the same on a central repository. The operators can access updated maintenance strategies, and manufacturer manuals while exchanging feedback on asset performance on the Asset Intelligence Network.

Empowered People

Irrespective of how far the manufacturing and business sectors are automated, people are still essential in them. The human resource will fill in positions that cannot be automated, complete complex tasks, and make intuitive decisions. Every sector will thus need empowered people who are the most productive and make the best decisions. The Empowered People solution in SAP’s Industry 4.0 aims to integrate robotics and AI with humans rather than replace the latter. This means giving them the necessary tools that will empower them and make them better at their jobs. Here are some of the features of the Empowered People solution from SAP:

- Environment, Health, and Safety (EHS) Management

With the range of workplace hazards lurking in your workplace, you cannot afford to overlook the mitigation of the same. SAP’s EHS management feature allows authorities to identify, evaluate, and mitigate the environment, safety, and health risks in your work environment. It also manages the chemicals used in different sections, monitors industrial hygiene, and reduces the impact of your activities on the environment. With these steps, an organization can safeguard its operational safety and efficiently manage its EHS system.

- 3D Visualization

Without optimal communication between the different players that determine your profits, you might have to close down within a few years. As part of its Industrial 4.0 solution, SAP offers the 3D visualization feature that improves communication among staff. With unhindered communication, decision making is accelerated, quality is improved, and productivity is optimized. 3D Visualization translates 3D CAD files into lightweight formats and creates 3D animations of your complex files.

- Work Manager

This is meant for work crews. With it, they can create work order management schedules, and access their maintenance data online and offline. Work crews using the Work Manager feature on the Empowered People solution can also access flexible SAP backend and mobile device support. The feature reduces downtime and maintenance backlogs while shifting capital expenditure to an operational expense.

Summary

The above solutions for Industry 4.0 are delivered by SAP as SaaS and can thus be accessed from all web browsers.

IDC, an independent consulting and marketing research organization for telecommunications and IT, anticipates that at least 50% of value creation will be digitalized by 2021. For mid-sized and small businesses, digitizing their processes early will mean retaining their competitiveness and being compatible with future value chain trends. If you digitally transform your company now, you can become one of the drivers of change in connected business places.